2019 Holz-Her "Lumina KAM_1594" Edgebander  Ended

Ended

Warehouse Auction - Tracy, Ca

Tracy CA

- Winning Bid : $40,400.00 USD Sold

- 152 Bid(s)

- High Bidder: n****n

Woodworking Machinery Auction - Tracy, CA ( Closed #61399469 )

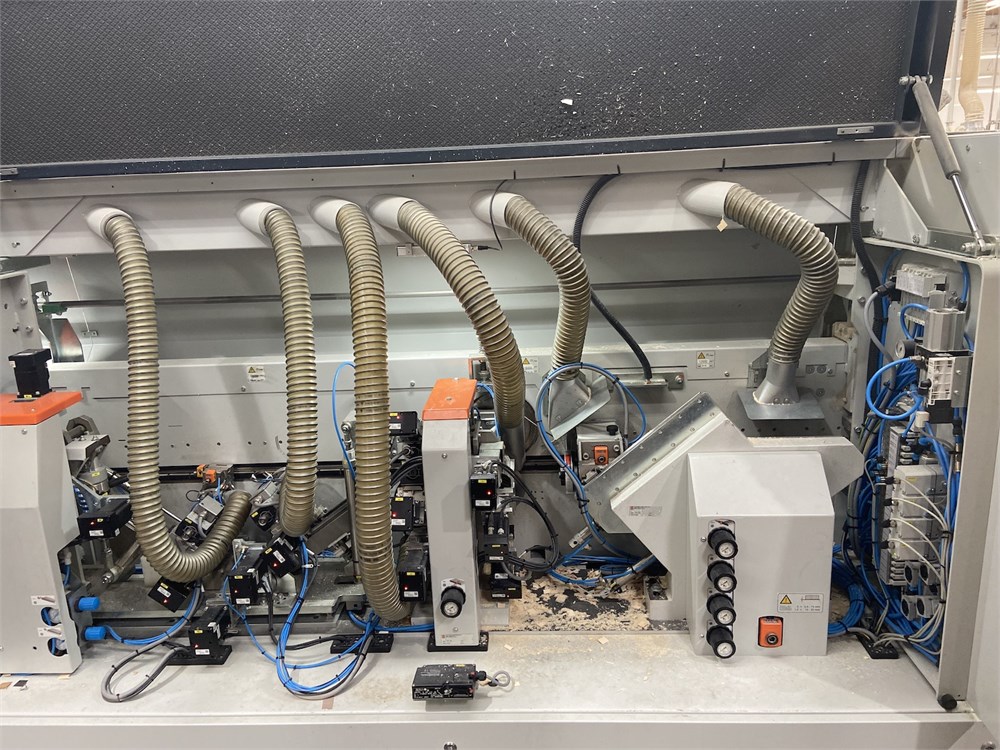

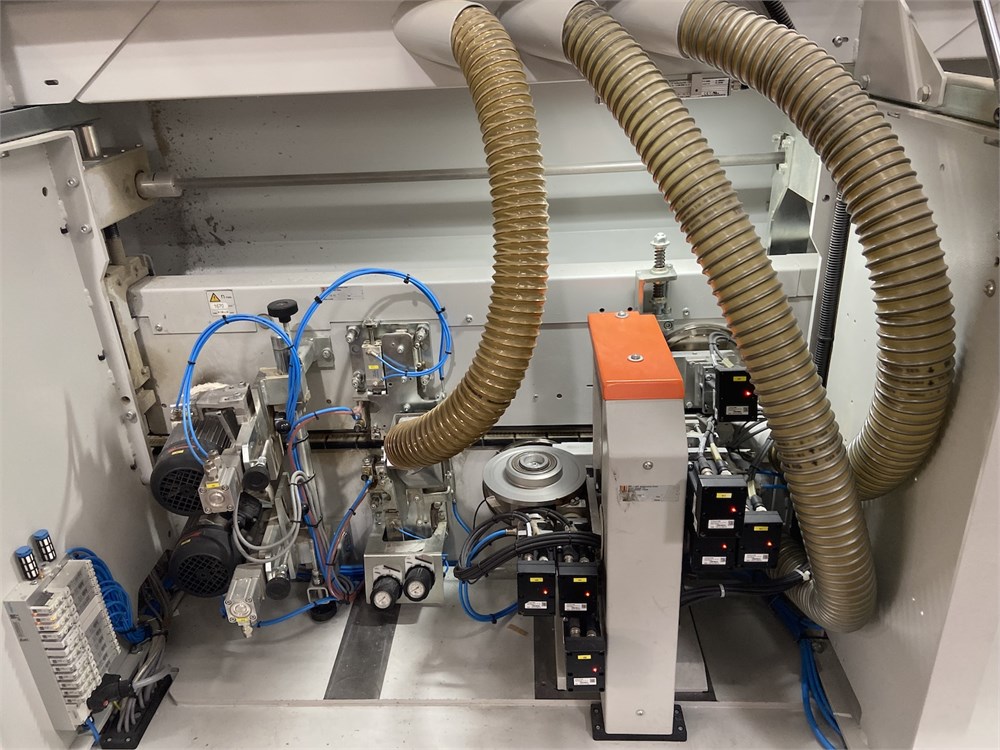

All assets moved to warehouse in Tracy, CA for convenience of buyers. Items include late model 2019 Holz-Her Lumina Edgebander w/ Laser, (2) Gannomat Trend CNC Drill and Dowel Insertion machines, SCM K208 Edgebander, SCM F410 16" Jointer, Several Ritter Machinery machines and more.

-

Item Location

2203 N. MacArthur Drive, Tracy CA 95376

-

Make

Holz-Her

-

Model

Lumina KAM_1594

-

Serial Number

202/1-903

-

Year

2019

-

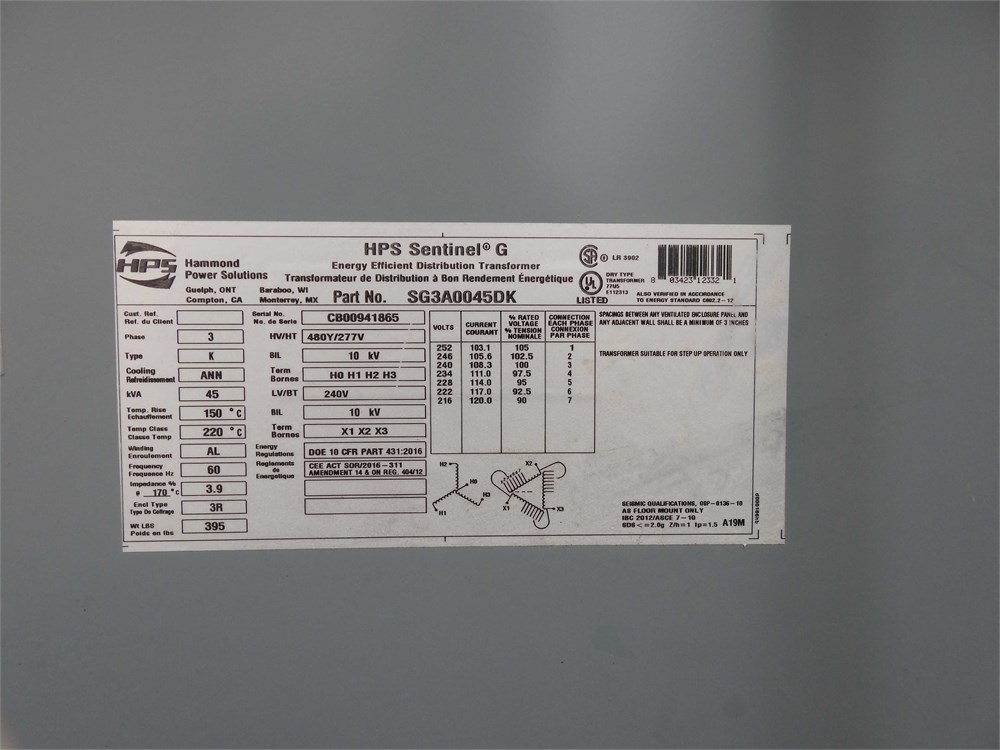

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

-

Final Removal Date

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

This is one loaded machine! Ready to ship and go to work for you!

-

Load Fee

$995.00

-

Lot Notes

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

page views

1380

2019 Holz-Her "Lumina KAM_1594" Edgebander

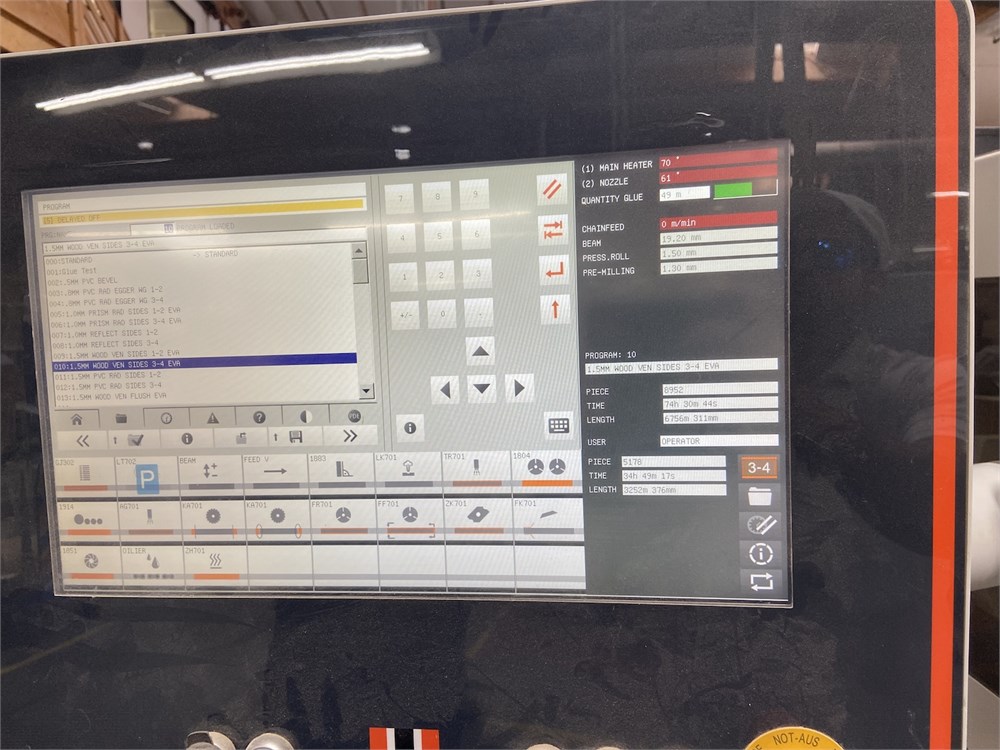

Edge Control

- 21.5" touch screen color monitor - standard feature.

- Graphic user interface, all information displayed in plain text and/or graphic form.

- Simple operation – rotating and swiveling control panel at eye height.

- Programs are simple to call with program names and numbers.

- Large program memory for all desired applications.

- Individual selection of units with the functions as basic setting possibilities for nominal values, path points and tool corrections.

- Service reports in clear text.

- Individual management for up to ten users with password protection and individual authorization.

- Network connectivity.

- Online maintenance, rapid exchange of data with HOLZ-HER service department.

- Barcode interface.

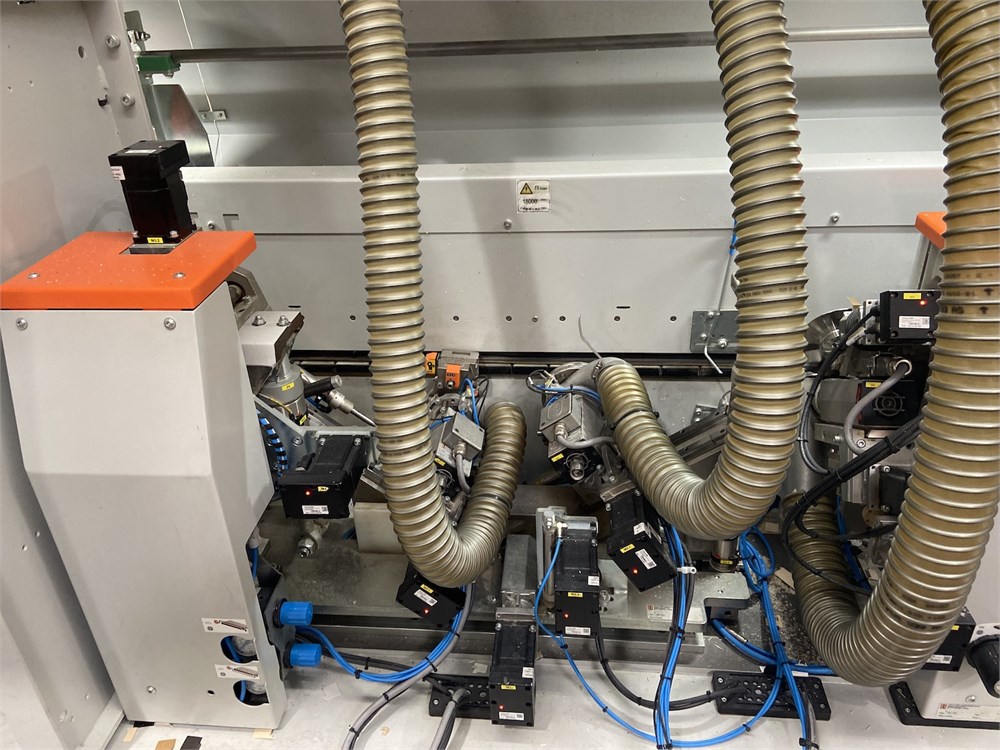

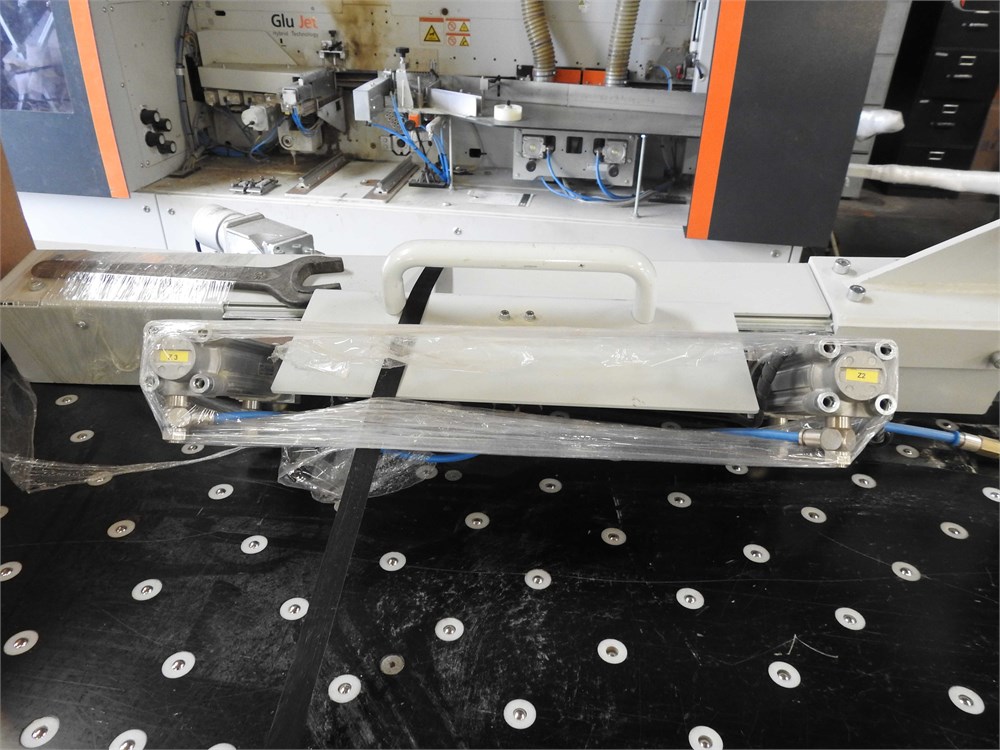

SYNCHRO edging feed

- The edging magazine with synchro-drive. With its synchronous adaptation to the feed rate, this edging magazine guarantees short intervals between workpieces and simultaneously optimizes edging protrusions.

- Small feed angle thanks to nozzle design - easy feeding of solid wood edging up to 20 mm.

- Guide Unit for Short Parts

- Heavy-Duty Pull-out Support Rail

- Air Flotation Infeed Table

Jointing cutter

- Cut edging often has small tears in the top layer. The jointing cutter unit ensures perfect glued surfaces and prepares the panels for the gluing process. Equipped with two 70 mm dia. diamond tipped cutters with AirStream technology (HOLZ-HER / LEUCO Patent). Including HSK32R chuck. For greater rotary precision, to provide smoother running, longer service life and preserve tools and motor.

- With symmetrical diamond tipped cutters (dia. 100 mm) for maximum joint quality and long service life. Automatic height adjustment with two NC servo-axes.

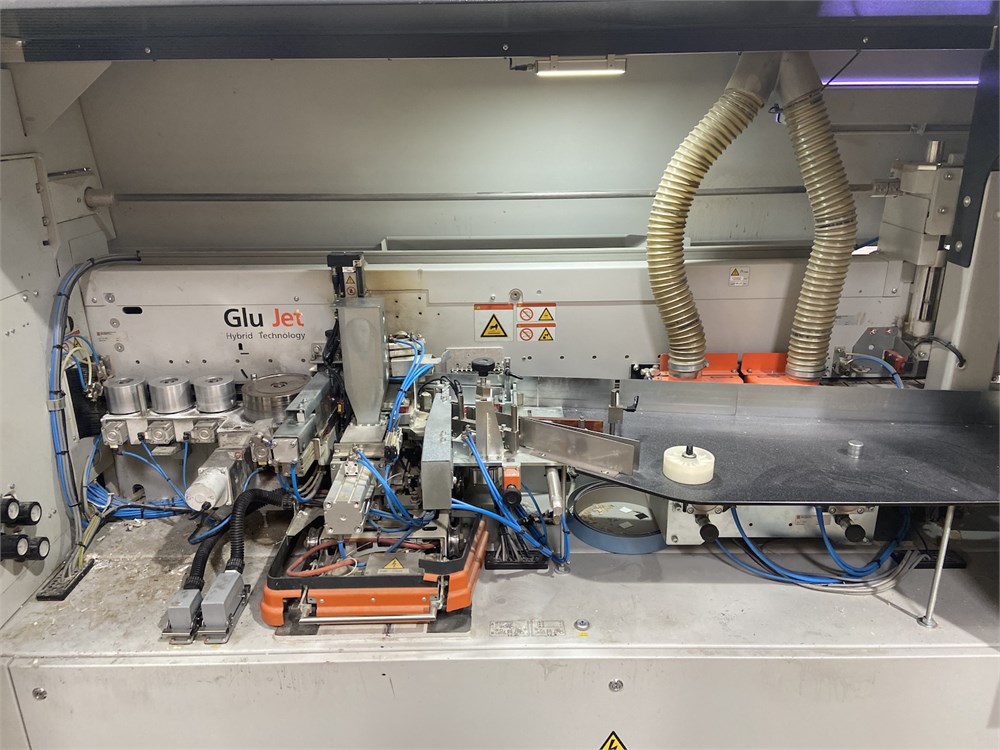

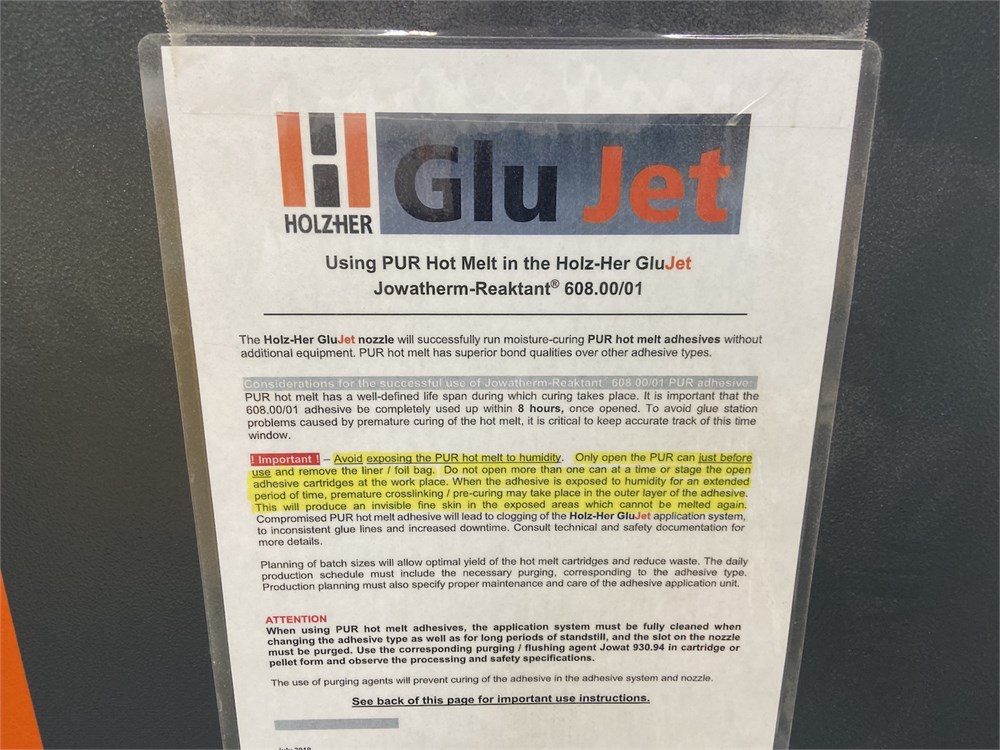

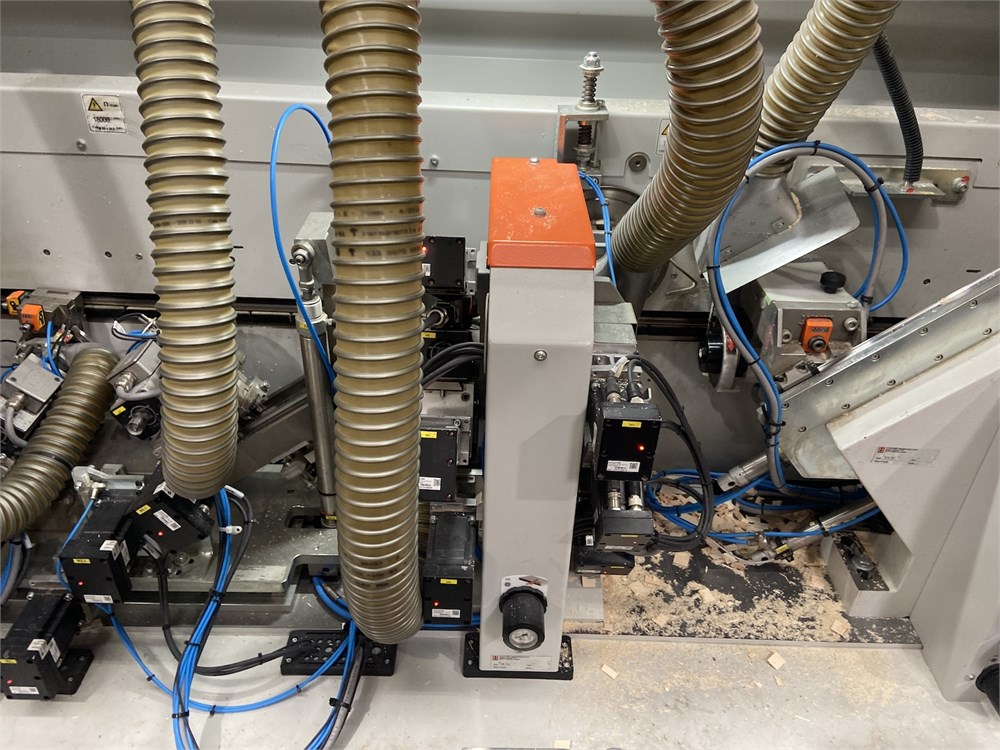

Glu Jet automatic - change-over gluing station

- The pressure cylinder presses the cartridge or granules against the heater elements. After reaching a certain position, the sensor sends a replenishment signal to the control. As long as glue is being applied to a workpiece, charging is delayed until the work is finished. The pressure cylinder retracts automatically, a new cartridge or fresh granulated material is gravity fed from the cartridge supply shaft into the heating chamber where it is again pressed against the heating elements.

- Purging hole for automatic cleaning system – e.g. cleaning out PUR glue.

- The Glu Jet automatic is attached to a set-up carriage alternating with the LTronic unit as a glue application system with automatic change-over. Change-over is accomplished within a maximum of two minutes by a high precision interface with HSK chuck and CNC technology.

Glu Jet PUR 2K adhesive application system

- With the Glu Jet, you can process standard commercial 2 kg PUR glue cartridges, which are significantly more economical than conventional PUR granules or the smaller 300 g PUR glue cartridges. This investment amortizes itself quickly for companies using more than approx. 500 kg of PUR glue per year, i.e. customers with an average glue consumption of approx. 2 kg per day. This corresponds to a processing quantity of approximately 100,000 running meters per year. The savings for glue costs alone already amortize the machine during the second year.

- As accustomed from the Glu Jet, the heat-up time is unbeatably short - now only 3 minutes for the Glu Jet.

- The new glue station is designed as a changing station with HSK adapter. This allows the station to be removed easily using a change-over carriage, making it even easier to clean the glue application nozzle.

- Integrated, fully-automatic purging routine

- Motor-driven nozzle height adjustment

- Remaining glue monitoring

- The control continuously indicates how many more meters of edging can still be processed with the current filling.

- The station can be precisely cleaned at the touch of a button with the right purging volume as well as correct temperature and purging timing.

- Glue melting capacity 60 mm workpiece height x 6000 mm workpiece length at 20 m/min

- Invisible joint look using new thin film technology

- In addition, Glu Jet’s low maintenance requirements and energy efficiency reduce costs

- The sealed system prevents unpleasant odors due to escaping glue vapors

- Heat-up time only 3 minutes

- Waterproof quality for your entire production

- The PUR glue can remain in the system for up to 48 hours

Motor-driven pressure unit

- Synchronously driven pressure unit with automatic adaptation to feed rate and NC servo-axes for motor-driven adjustment to correct edge thickness. Straight and tapered pressure rollers for perfectly glued joints.

Trimming unit

- Most powerful trimming unit in its class – edge cross-section 20 x 65 mm. With hardened linear guides for high precision trimming results up to edge thickness of 20 mm.

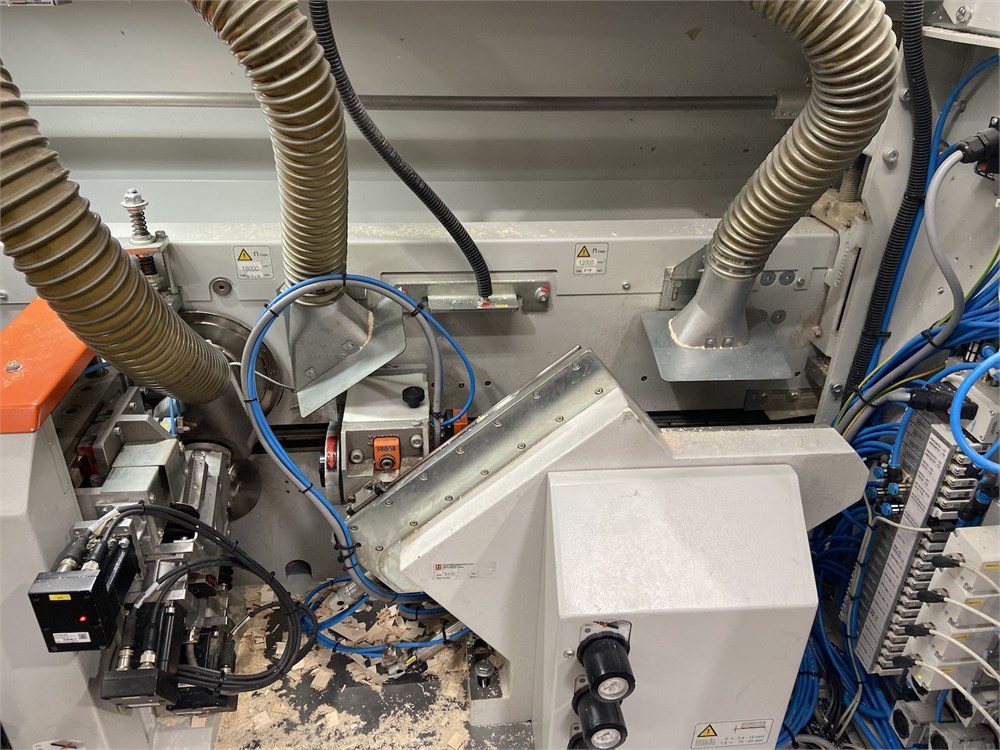

Cutter unit

- Heavy duty floor-mounted machine with shock-absorbing mounts and large sensing rollers for perfect results even at high feed rates.

- 100% repetition accuracy at the touch of a button based on zero-clearance mechanisms and six high precision NC servo-axes. Horizontal sensing with angular sensing rollers with chemically applied nickel plating developed especially for processing modern, high gloss edging.

Copy cutter unit

-

Copy cutter unit with four NC servo-axes as standard feature

- For cutting top and bottom longitudinal edges, copy cutting on vertical edges at front and rear ends, corner rounding and postformed corners. - Work height up to 60 mm workpiece thickness

- Unit adjustments on linear guides with central lubrication. With standard blast nozzles in front of sensing rollers to blow away chips in front of sensing areas. Including shelf program for optimum processing of shelves with rounded edges.

- Automatic pendulum sensor copies ends without material protrusion and leaves the optimum longitudinal edge protrusion for subsequent machining with the radius scraper.

Scraper unit

- 100% repetition accuracy at the touch of a button based on zero-clearance mechanisms and 6 high precision NC servo-axes.\

Flat scrapers with pre and post-sensing

- Clean surface finishing with pre- and post-sensing for high feed rates. 2 HW cutting edges, for use on 4 sides. Completely eliminates all manual finishing. Both units can be lifted automatically for special applications.

Spraying devices

- Spraying units for parting agents and cleaning agents for feed and discharge area. Anti-static, coolant and lubricant – electronically controlled by special nozzles - for a perfect edge finishing.

Buffing unit

- Polishing for maximum gloss; for complete finishing. Standard setup.

- Also available as oscillating version (optional)

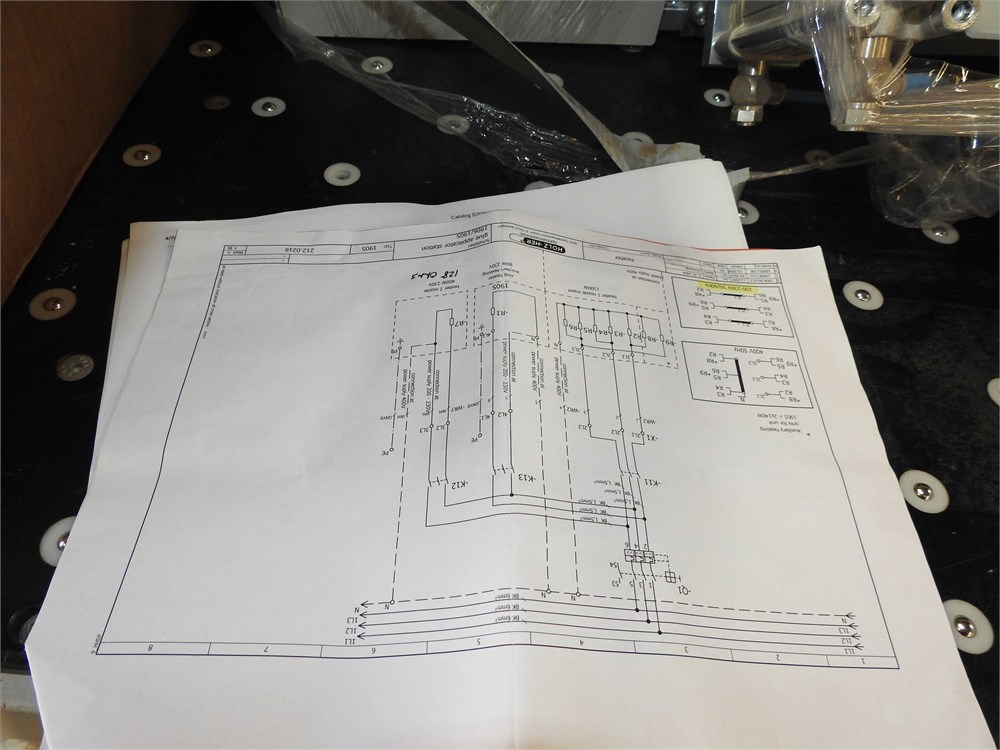

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available