SCM "Pack C 100" Auto Cardboard Box Machine - Hot Melt  Active

Active

Lancaster, SC

Lancaster, SC

-

Item Location

Lancaster, SC

-

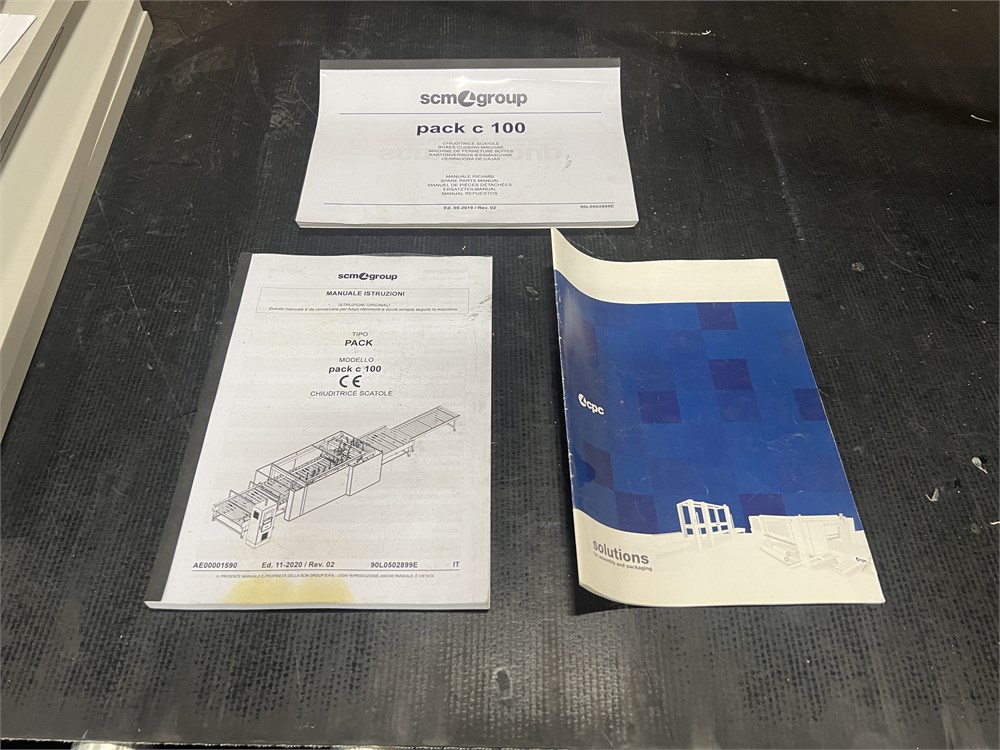

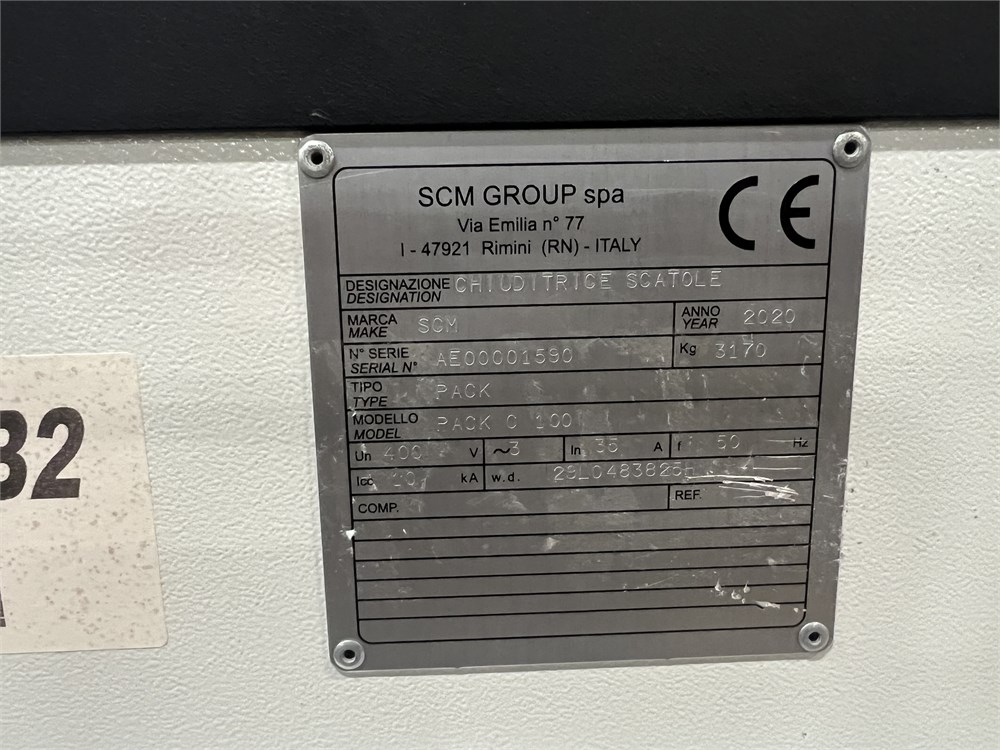

Make

SCM

-

Model

"Pack C 100"

-

Serial Number

AE00001590

-

Year

2020

-

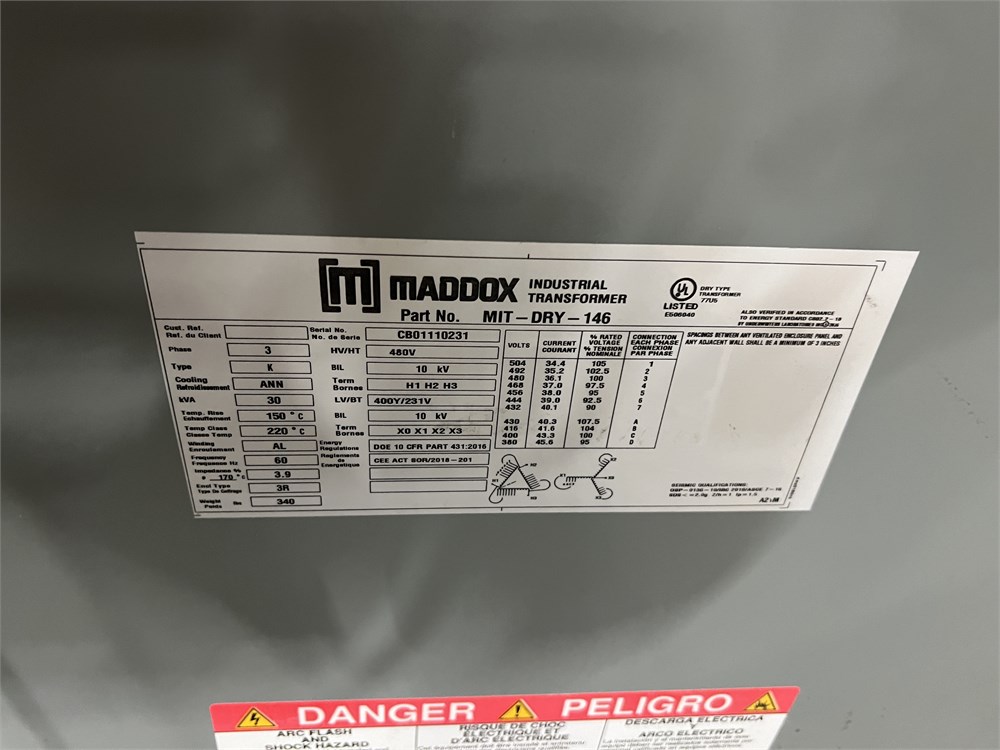

Phase

3 PHASE

-

Voltage

480 VOLT

-

Inspection Date

By Appt. Only - Please Contact Eric Beach - 704-608-9830 (text preferred)

-

Final Removal Date

-

Estimated Dimensions

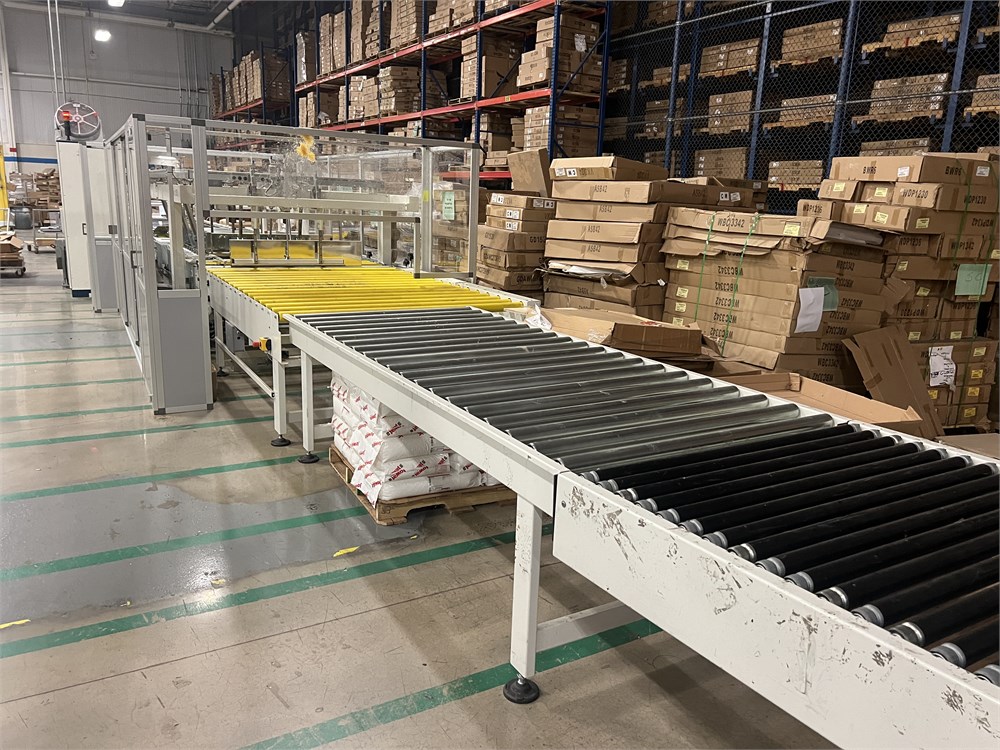

376" x 101" x 80"

-

Estimated Weight

7,000 Lbs

-

Seller Comment

See Documentation & Video

-

Load Fee

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Lot Notes

-

page views

1092

SCM "Pack C 100" Auto Cardboard Box Machine - Hot Melt

Roller conveyor width mm 1800 Roller pitch mm 125 Roller diameter mm 60 Working table height mm 900 +/- 30 Min. box length (external dimensions) mm 400 Max. box length (external dimensions) mm 2400 Min. box height (external dimensions) mm 25 Max. box height (external dimensions) mm 250 Min. box depth mm 250 Max. box depth mm 1050 Installed power (absorption) A 35

Cardboard box model (shape) : FEFCO 0410 Cardboard box dimensions tolerance : +/- 2 mm Creasings tolerance : +/- 2 mm Position tolerance between die-cutted/creasings : +/- 2 mm Angular tolerance (at right angle between length and width): 0.05 degrees max. Cardboard thickness : from 2.7 to 6.5 mm + /-0.2 mm

Welded and screwed structure. Shaped steel structure, protected by epoxy primer and two-component polyurethane coating. Mainly mechanical and pneumatic functioning. Automatic measuring of the infeeding box dimensions (in random mode).

up to 8 cardboard boxes for batch production (length = 1200mm) up to 5 cardboard boxes for batch production (length = 1200mm) WHEN USING PRINTING MACHINE

Cycle Infeeding roller conveyor with tilting PVC rollers to facilitate the box alignement to the reference stop fence. Double station for the closing of 3-flap boxes: first station for simultaneous longitudinal and front side closing; second station for the rear side closing. 3 vertical units for the box holding and simultaneous cardboard flaps closing by means of 3 stainless steel, vertical inclined units pneumatically controlled. Control unit for hot-melt gluing Melter for the glue distribution by means of 6 noozles (two on each side of the box to be glued). It is possible to lay single or double glue line on the three sides of the box, with no mechanical setup to be executed. The 2 glue lines height, in relation to the box base, is preset and can be mechanically modified in any case. Enabling and disabling of the second glue line by control panel (according to requirements). Dotted glue line on the longitudinal side to allow he closing of boxes with minimal height. Box positioning Side aligner controlled by a brushless motor in order to move the box on the first working station. Lower retractable steel stop fences for the correct in line positioning of the box, on the three sides to be closed. Outfeed roller conveyor with PVC coated rollers to maximize the execution speed

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view purchase history

LoginPlease log in to post a question

Login

There are no questions for this listing.