2020 CMS "BR5-1512S" Heavy Duty Vacuum Former - Portland, OR  Active

Active

Available for immediate purchase!

Portland, OR

-

Item Location

Portland, OR

-

Make

CMS

-

Model

BR5-1512S

-

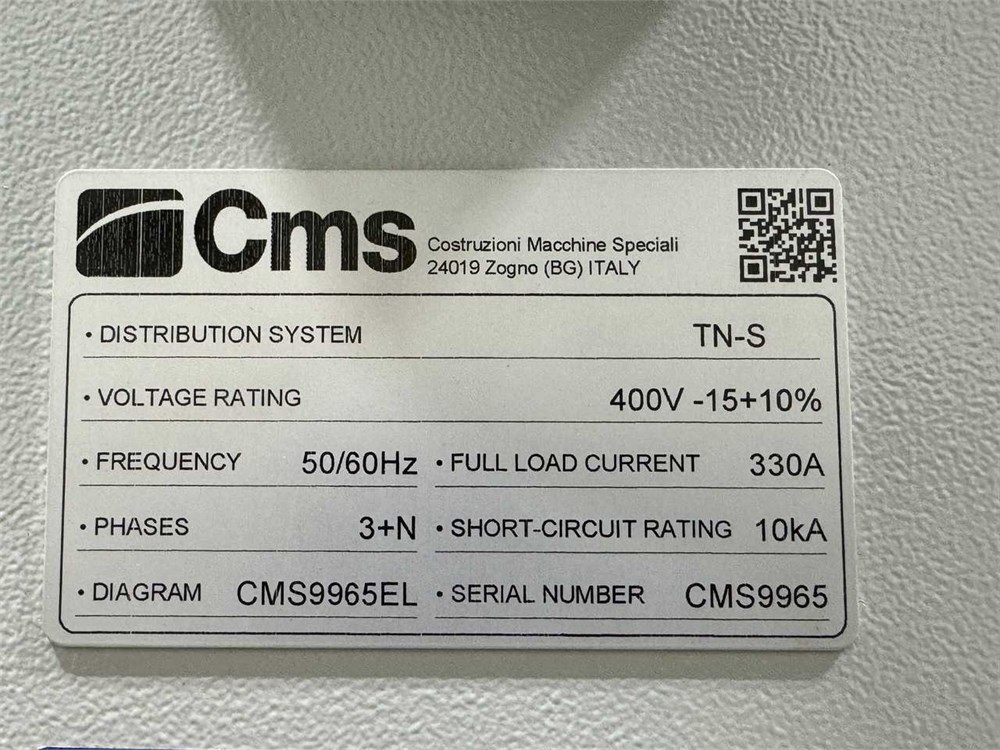

Serial Number

9965

-

Year

2020

-

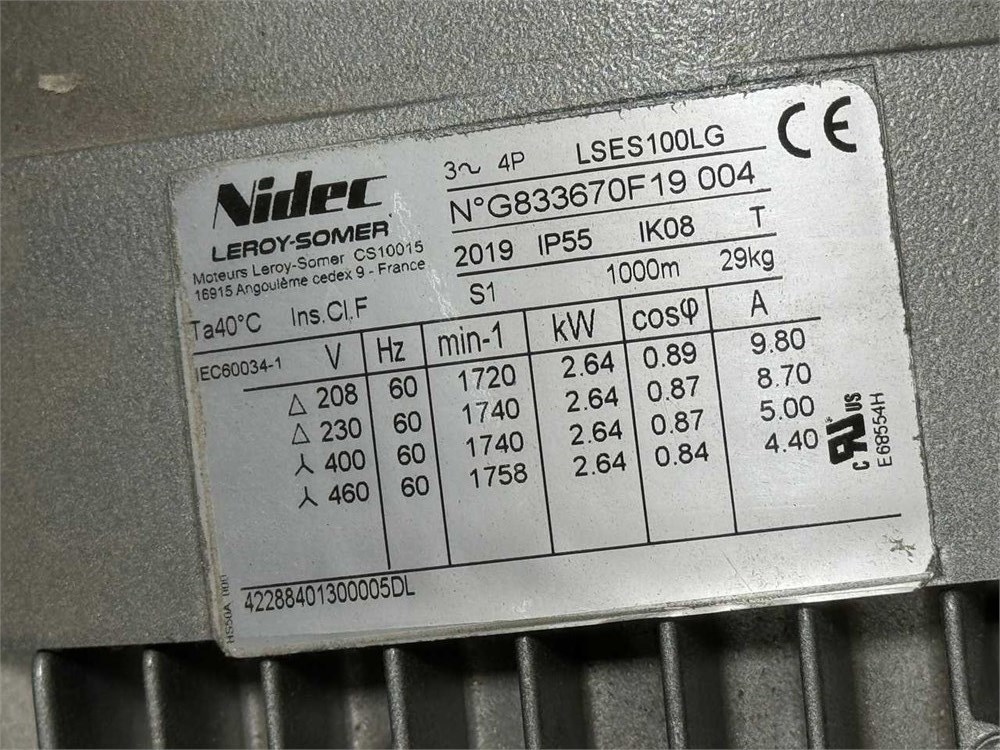

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

By appointment only, contact Josh Beauregard, [email protected], 207-332-9144

-

Final Removal Date

Two weeks after purchase date

-

Estimated Dimensions

15' L x 16' W x 156" H

-

Estimated Weight

25,000 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

1393

2020 CMS "BR5-1512S" Heavy Duty Vacuum Former

The BR5 model is a vacuum forming machine that produces top quality parts out of thermoplastic sheets

up to 10mm thick. With unmatched quality and reliability, the BR5 will ensure maximum productivity

with an easy to use HMI (human machine interface). The BR5 is equipped with multiple solutions for

sheet heating, mould changing, sheet management and cooling capabilities

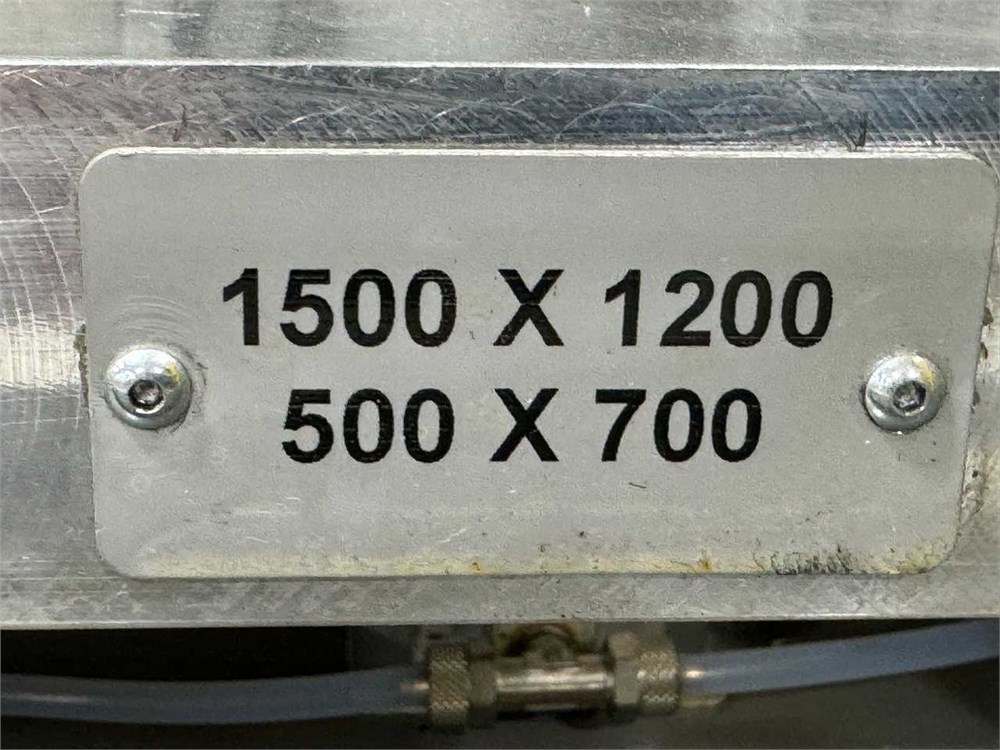

Max sheet size mm/in 1.560 X 1.260, 61.4” x 49.6”

Maximum lower frame size mm/in 1.500 X 1.200, 59.0”x 47.2”

Minimum lower frame size mm/in 500 X 700, 19.6”x 27.5”

Max mould height mm/in 600, 23.6”

Upper heater power kW 97

Lower heater power kW 97

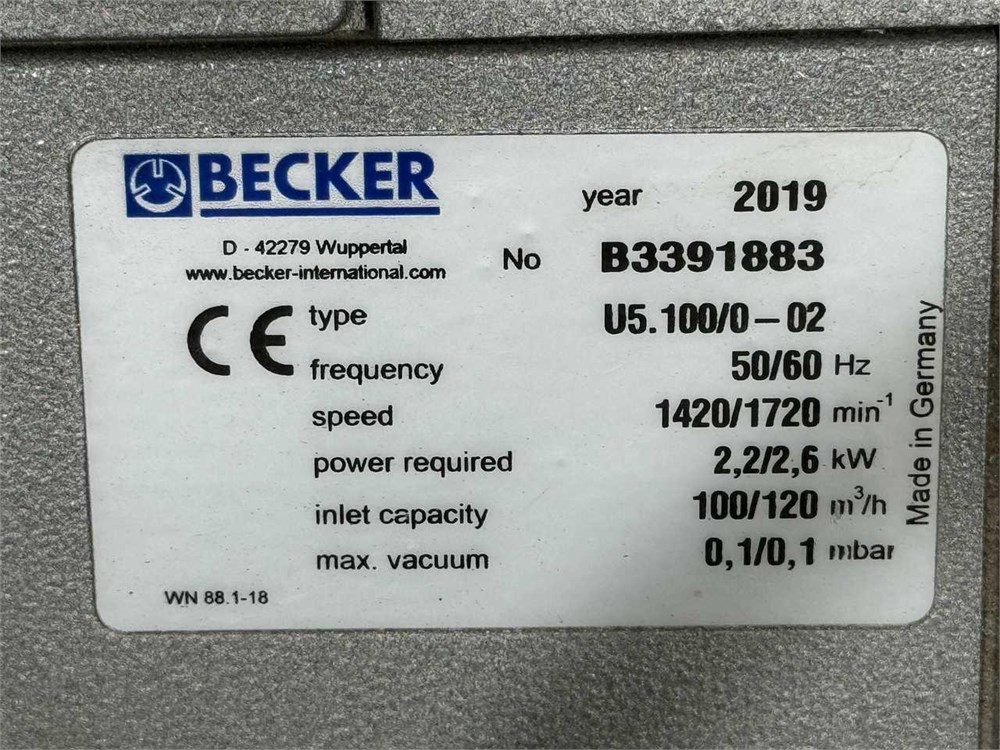

Vacuum pump rate mc/h 1 X 100

Total power installed kW 220

Compressed air pressure Bar 6

Power supplyV 400

phases 3+N(TT or TN-S)+T

Noise level Db(A) Leq 73

AUTOMATIC SHEET LOADER AND PART UNLOADER

This system allows the operator to load and unload the sheet material both prior to the thermoform

process and following part completion. The auto-center and management function will automatically

move the sheet into proper orientation before advancing the sheet into the thermoform station. The

loading trolling is controlled with vision and operated using high quality servo motors.

Loader Positioning : Left

NEW Sheet centering device

The automtic sheet centering system mechanically aligns sheets prior to loading

to ensure proper orientation in the machine. The Length of the sheet is

measured using an optical sensor during the loading process to align the sheet

perfectly for the thermoforming process. Access to the loading area is allowed

during a work cycle enabling the operator to load and unload without stopping

production.

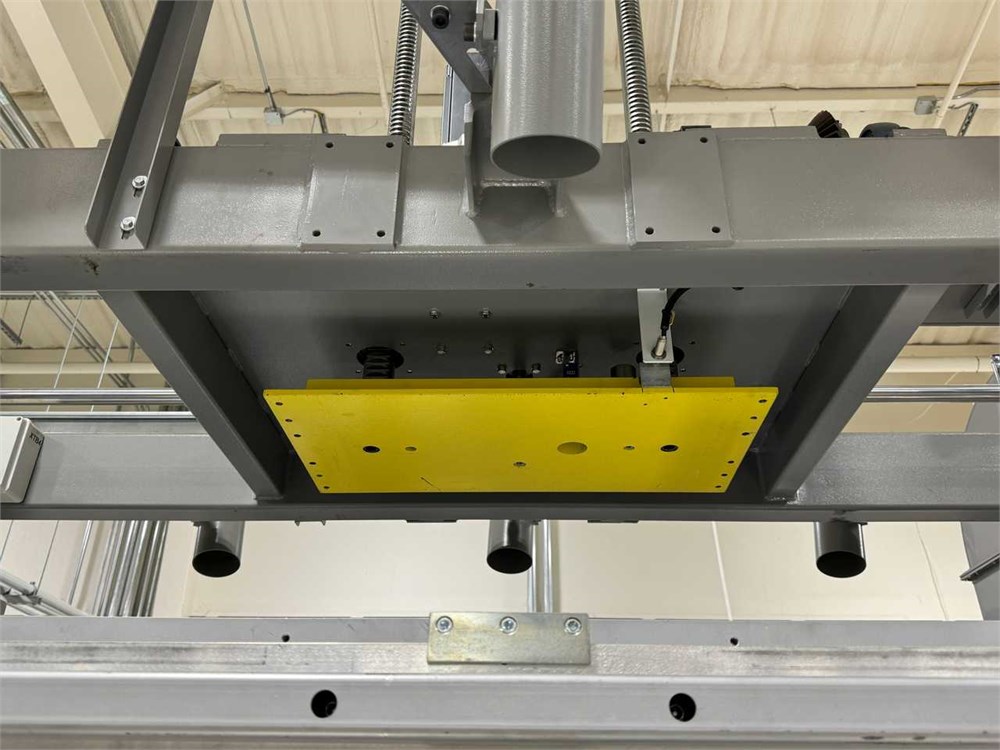

PLUG ASSIST

Advanced plug assit uses brushless servo motors allowing operator control of feed speed through the

control interface. System allows storage of parameters to ensure accurate and repeatable assist.

System is equipped with an electromagnetic brake and security system that locks motion of positioning

axis in case of ESTOP or powerloss.

TOOTHED BLADE – 100% PARAMETER SHEET CLAMPING

Optimal clamping is achieved between the plate and frame with a toothed

blade and sealing gasket. This system ensures the sheet is completely

secured during the thermoforming process.

AUTOMATIC ADJUSTMENT OF CLAMP FRAME DIMENSION

(LONGITUDINAL BEAMS CENTER DISTANCE AND TELESCOPIC BEAMS)

The frame is made of heavy gauge steel to maintain its rigidity. Using

brushless servo motors the frame size adjust to the proper dimensions.

This system allows for more flexibility with mould design and sheet

management. When the sheet thickness varies, no adjustment is required.

Servomotors control the clamp frame dimension continuously. The control

cycle is automatic and can be saved in programs.

AUTOMATIC WINDOW FRAME (REDUCTION STROKES X-1000

MM, Y-500 MM)

The automatic window frame allows the flexibility in the thermoforming

process. Dimensions are controllable up to 1000mm in X and 500mm

in Y.

The window plate is made of aluminium and it is complete with copper

pipes inserted into the plates for complete thermostatic control.

THERMOREGULATOR REDUCTION PLATE

Thermoregulator unit controls temperature of Plate up to 95 degree C using water.

AUTOMATIC HEATER MOVEMENT BY SERVOMOTOR

Heating elements are managed with two servomotors creating a “reciprocating” motion (patented)

designed for optimal heat distribution on the entire surface of the sheet. Motors are backed up with a

battery set to safely move the heaters into the start position in the event of a power loss.

HALOGEN LAMPS (SPEEDIUM)

The heaters are equipped with halogen lamps (800/300 W),

controlled individually both in percentage and in power, which allow

to reduce heating times and to maintain a low temperature while the

machine is working; thereby the productivity increases.

The heating elements are wired with nickel cables.

GLASS-CERAMIC COVER

Bottom heater is equipped with glass-ceramic covers.

OPTICAL PYROMETER

The optical pyrometer controls the sheet temperature.

MOULD PLATE

The mould plate is equipped to control the temperature of the mould with no. 2

plugs. The movement of the plate is managed with an electronic gantry by means

of two servomotors.

THERMOREGULATOR BY WATER FOR MOLD

Thermoregulator by water with high cooling capacity. Heating power: 9 kW/280°F

QUICK MOULD CHANGE SYSTEM

The quick mould change system provides the operator a quick and easy way to change the mould to

maximize production and minimize change over time. The plate is easily removable by a mechanical lifting

system inside the machine structure. Once fully lifted for extraction a trolley is locked into place and the

operator can easily slide the mould plate onto the trolley by way of roller bearings on the trolley. Once the

mould is removed and a new mould plate is introduced to the machine it is automatically centered.

TROLLEY EQUIPPED WITH PNEUMATIC MOULD LIFTING SYSTEM

The mould trolley is equipped with a pneumatic system which lifts up the mould

by four screws (pneumatically controlled) in order to allow load and removal

of trolley by forklift.

VACUUM PUMP 165 MC/H CAPACITY

The system consists of two oil blade pump (165 mc/h each).

Vacuum and vacuum management is equipped with three modes in order to

achieve proper cycles and quality.

FORMED PART COOLING

Centralized Formed Part Cooling

Formed part cooling occurs by high capacity and adjustable (in all the directions)

draw holes.

A big fan installed on the floor supply the air at the draw holes.

PYROMETER FOR FORMED PART COOLING CONTROL

Positioned on the machine, above the part, the pyrometer takes thermal

readings of the thermoformed part and controls the temperature during the

cooling process.

PROPORTIONAL SYSTEM

Both vacuum and air flow functions are controlled by proportional valves. These

valves allow for continuous control of pressure and flow rate. The values are

saved for future part programming.

The pressure chamber for managing pre-stretch is operated by an electro

fan and not compressed air. The controllable electro fan allows for better

air volume management.

SENSOR FOR PRE-STRETCH BUBBLE CONTROL

The photocell measures the pre-strech bubble height allowing the controls to

automatically optimize airflow. Pre-Stretch optimal height can be fixed at set up and

managed automatically by way of the photocell.

SHEET SAG CONTROL

The pressure system, airflow, optical photocell and heating elements work together to create “Zero Sag”

during the heating phase. Zero Sag allows for the highest quality of thermoformed parts.

SHEET SAG SAFETY SYSTEM

An emergency photocell (laser), fixed on the machine body, ensures the lower

heater safety.

An emergency photocell, fixed on the movable frame above the transversal

bars, ensures the upper heater safety.

MACHINE BODY COOLING

An automatic exhauster allows the machine frame to be cooled at the same

time the mould cooling is in process. In this way machine distortions and mould

overheating are avoided.

FRONTAL DOORS

Frontal doors provide a barrier for protection and also make mold

management very easy. The doors are equipped with proximity switches to

ensure operator safety during production.

SAFETY

A laser curtain is installed in front of the machine and is equipped with lateral covers for

both laser and operator safety. All other access doors are also equipped with proximity

switches for operator safety.

PLC AND CONTROL SYSTEM

The machine is managed by a PLC controller and touch screen interface. All elements of the Thermo

process can be addressed from the control panel. The system allows for heating parameter storage in

order to reduce the reoccurence of errors. The storage is possible on both hard disk or USB. Diagnostic

features allow operator to see any anomalies in the cycle visually on the control panel. The operator

inteface also allows for the operator to run a complete manual cycle.

The system allows for online access for trouble shooting by a CMS technician via

the 24hr hotlineand comes standard with Industry 4.0 capabilities to ensure proper

management visibility into the production process.

ELECTRICAL CABINET

A separate electrical cabinet in rigid anodized aluminum structure is located beside

the machine, dust insulated, in which all the main electrical and electronic parts for

the machine control are installed. Protection level: IP 54.

An air conditioning system keeps the internal temperature below 35 degrees C (95

degrees F.) The electrical cabinet is located on the right side of the machine

with respect to the loading position, unless otherwise noted under the included

equipment section.

OPC-UA

Machine connectivity using Industry 4.0 standard OPC-UA protocol makes it possible to read process

parameters, machine status, alarms and productivity values.

OPC-UA also allows real-time messages to be sent to operator(s) to optimize production capacity.

INSTALLATION DATA

All CMS machines adopt the neutral wire connection to avoid any electrocution risk for the operator.

Voltage: 480 volts, 3 phases, 60 Hz. (or as specified by the customer). The voltage specified must be

within +5% to –5% of the nominal line voltage.

The machine is supplied with a UL transformer with the primary voltage as specified by the customer and

the secondary voltage of 400 volts, 3 phases. 60 Hz.

The machine can be connected (either directly or by means of a transformer) to the TN (TN-C; TN-S)

supply systems.

If not, the customer shall provide for a secondary, earthed star-to star transformer, placed on line (before)

the machine control board.

Since the electrical board contains equipment that may generate a continuous component of the fault

current, we suggest to use a delayed-action (selective) device type A, or better type B if available, with 0.3

A adjustable differential current, for differential protection (not compulsory for the machine).

MACHINE COLORS

CMS standard colors: Light Grey RAL 7035 and Dust Grey RAL 7037

MACHINE COMPLYING WITH CE STANDARDS

The machine complies with the applicable parts of the following Directives:

Directive 2006/42/CE

Directive 2014/30/EU

CMS machines are designed and manufactured in compliance with the European Directives cited in the

Conformity Certificate released with the machine documentation.

The User’s and Maintenance manual is the cornerstone for all information related to machine use and

maintenance, and therefore to the operators’ safety. For this reason, the customer shall acquaint himself

with the various chapters (among which Allowed Usage, Residual Risks, etc.)

In case of machines bound for the American market please note what follows:

From the electrical point of view the CE adopts the European and international ISO EN 60204-1

regulation, that mostly differs from the corresponding UL, CSA;

From the visual warning point of view, the CE does not accept the usage of warning signs, but

the content of the User’s and Maintenance Manual applies.

The CE conformity certificate testifies CMS’, the supplier’s, “good faith” to comply with European legally

binding laws.

Checking the regulations in force in non-European countries is the customer’s liability.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view purchase history

LoginPlease log in to post a question

Login

There are no questions for this listing.