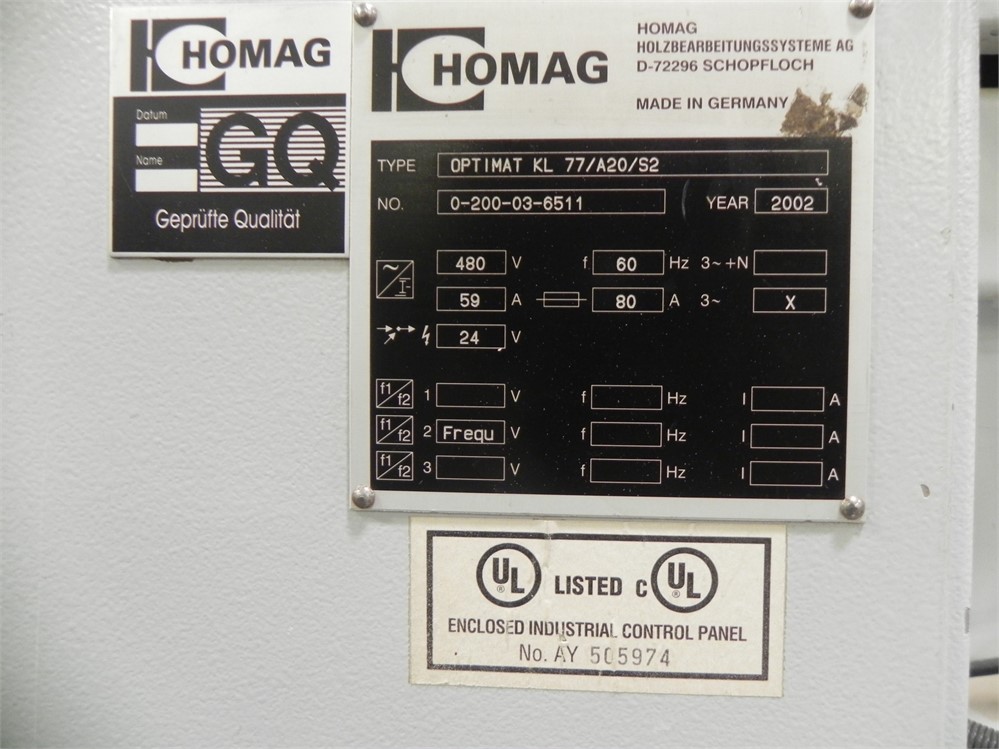

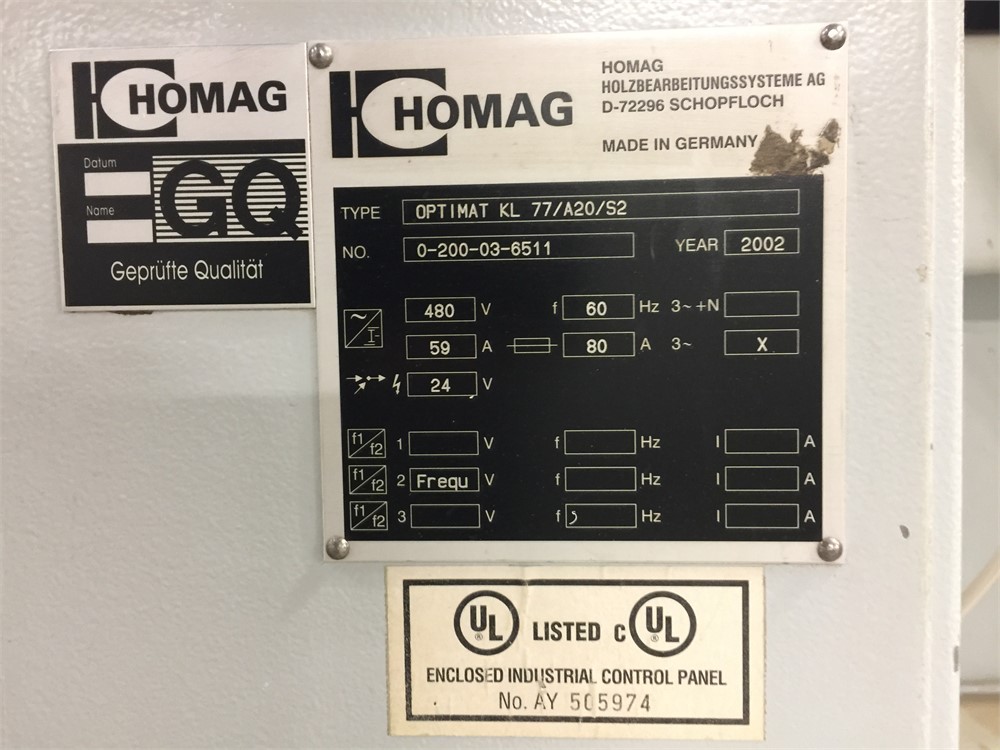

HOMAG "OPTIMAT KL 77/A20/S2" HEAVY DUTY EDGEBANDER, YEAR 2002  Ended

Ended

BARBOSA CABINETS, EXCESS MACHINES NO LONGER NEEDED, TRACY CA

- Starting Bid : $1,000.00 USD

- 0 Bid(s)

BARBOSA CABINETS - ITEMS NO LONGER NEEDED FOR PRODUCTION - TRACY CA ( Closed #20042652 )

EXCESS MACHINERY NO LONGER NEEDED FOR BARBOSA CABINETS, TRACY CALIFORNIA. MOST ITEMS HAVE BEEN MOVED TO TRACY CALIFORNIA WAREHOUSE FOR THE CONVENIENCE OF BUYERS. LARGER ITEMS SUCH AS CNC, BEAM SAW, AND EDGEBANDER ARE STILL LOCATED AT THE BARBOSA CABINETS MAIN FACILITY IN TRACY CALIFORNIA. ITEMS INCLUDE 2005 WEEKE OPTIMAT BHC-350 CNC PT. TO PT., 2004 HOLZMA HPL BEAM SAW, 2001 HOMAG OPTIMAT KL 77 EDGEBANDER, LOTS OF TIGER STOP SYSTEMS WITH UPCUT SAWS, UNIQUE MACHINE 3250 SHAPE AND SAND, NORTHTECH STRAIGHT LINE RIP SAW, AND MUCH MORE. ALSO UP FOR NEGOTIATION IS A 2017 STEMA SRL TABIT LOCK DOWEL DRAWER MACHINE.

-

Item Location

1905 N. MACARTHUR DRIVE, SUITE 110, TRACY CALIFORNIA 95376

-

Make

HOMAG

-

Model

OPTIMAT KL 77/A20/S2

-

Serial Number

0-200-03-6511

-

Year

2002

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Inspection Date

EMAIL [email protected] OR CALL 209-832-0100

-

Final Removal Date

JANUARY 24TH, 2020, EXCLUDING WEEKENDS

-

Estimated Dimensions

28' X 46" X 79"

-

Estimated Weight

APPROXIMATELY 7000 LBS.

-

Seller Comment

-

page views

1621

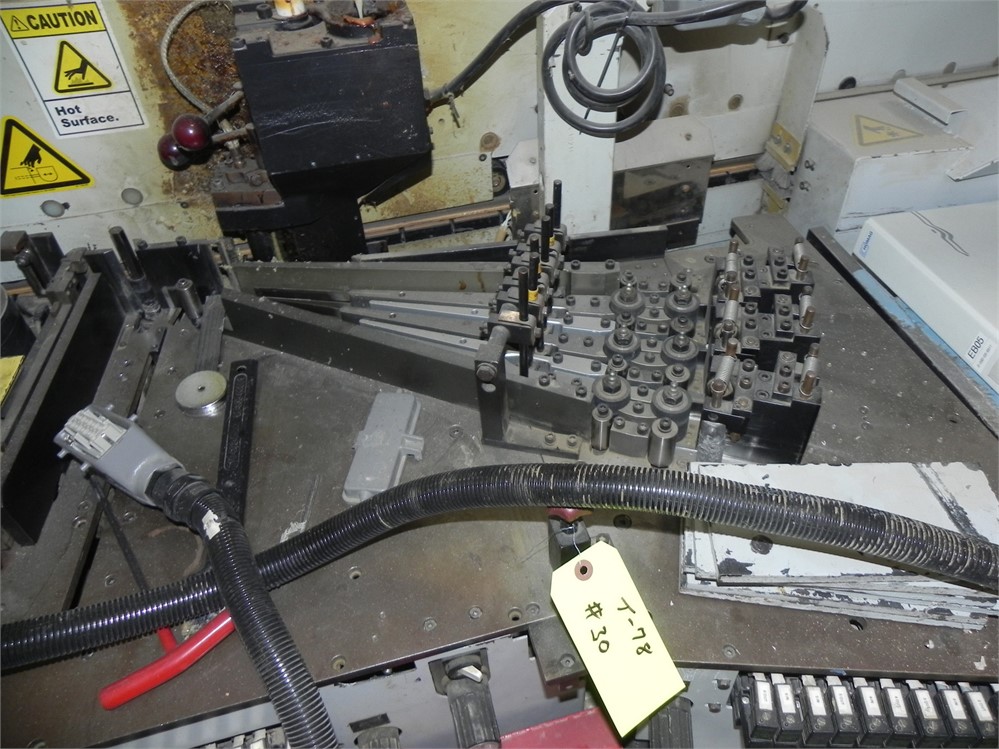

HOMAG MODEL #OPTIMAT KL 77/A20/S2 HEAVY DUTY AUTOMATIC EDGEBANDER MACHINE

480 VOLT, 3-PHASE

YEAR 2002 BUILT MACHINE

SERIAL #0-200-03-6511

***SPECS AS PULLED FROM MANUFACTURER WEBSITE, PLEASE DO OWN DUE DILIGENCE AS TO EXACT SPECS. OF THIS MACHINE:

Features and Specifications:

- Capacity Specifications: 0.4 - 20 mm Edge thickness cap.,min. panel width 55 mm (2-3/16") for panel thickness12 - 22 mm (1/2" - 7/8") and under;

- 100 mm (3.9") for panel thickness over 22 - 60 mm (7/8" - 2- , -5/16"); for up to 3 mm Coil stock, HPL, and strip stock up to 20 mm (3/4").

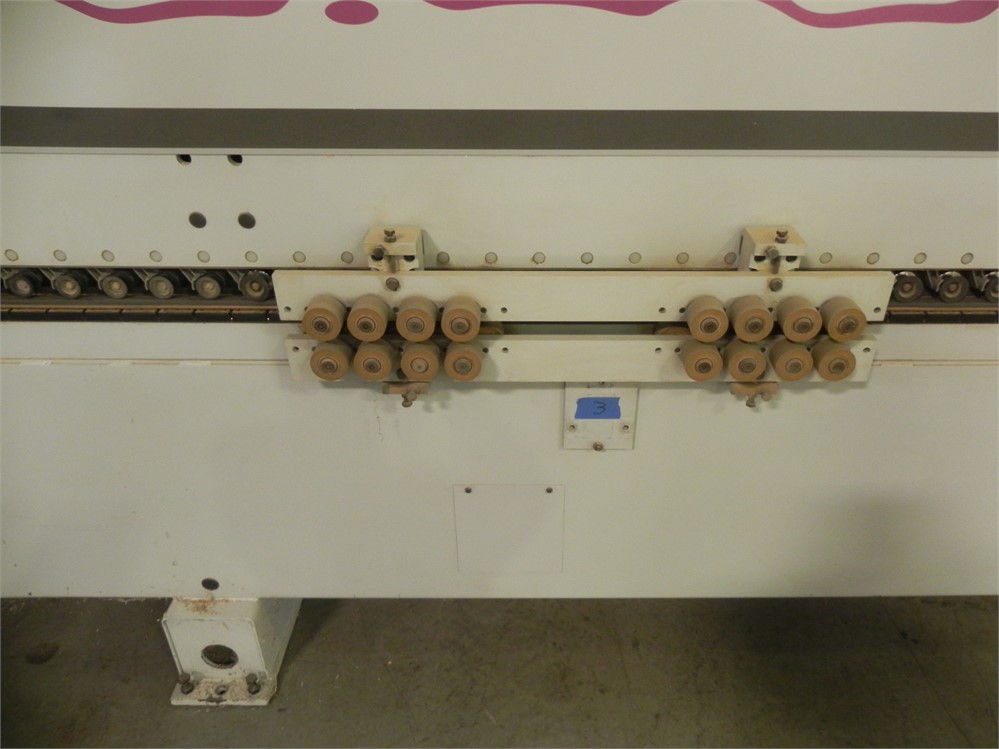

- Top pressure beam with: Double-wide compound Vbelts;80 mm wide feed track chain plates, vulcanized rubber insert pads, and Auto-Lube; variable feed speed from 18 - 24 MPM (59 - 79 FPM); 950 mm height/working level infeed

- Pre-Milling Station with: (2) 3 kW - 150 Hz, 9,000 RPM Motors, panel blowoff device; 2-position infeed fence (on/off), SIKO digital manual fence control. Panel Pre-Heater with: Quartz lamp for heating substrate edge before glue application.

- Edge Feeding device equipped with: Automatic coil magazine for quick coil changeover; strip feeder for up to 20 mm (3/4") solid wood banding.

- "Quick Melt" Glue System with: Reversible glue roller applicator; pressure roll section with (1) large dia. driven and (6) idle rollers; manual adjustment of pressure zone through SIKO digital counters for different edge thicknesses.

- Double motor front & rear end trim, straight & chamfer trimming (0.8 HP - 12,000 RPM ea. motor).

- Top & Bottom flush trim (2 HP - 12,000 RPM ea. motor).

- Profile Trimming unit "FK13" to process overhanging edges and trimming around the leading & trailing edge (0.75 HP each motor), 8-position tool changer .

- Edge Scrape Super-Finishing unit for thick PVC/ABS with chip collection box.

- Top & Bottom Flat Glue Scraper to remove potential glue squeeze-out.

- Top & Bottom oscillating buffing unit (two 0.33 HP - 1,650 RPM motors).

- "HOMATIC NC 16" controller features with Keypad & LCD display, stores working programs and controls functions of workstations, allows fault diagnostic and more etc.

- Complete with: PLC controlled, motorized beam height adjustment; servo adjustments on Top & Bottom flush trim, and servo controlled Scraper Stations.

- Electronic DC brakes on all trim motors sound cabins for all trim workstations and adjustable outboard panel support.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginLOADING FEES WILL BE ADDED TO EACH LINE ITEM SO PLEASE CHECK LOAD FEES ASSOCIATED WITH ITEMS THAT YOU ARE BIDDING ON. LOAD FEES ARE FOR LOADING ONTO FLAT BED TRUCK OR TRAILER ONLY.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME. CREDIT CARD WILL BE ACCEPTED FOR PAYMENT FOR INVOICES UNDER $2000.00 HOWEVER A 2% PROCESSING FEE WILL BE ADDED TO THOSE INVOICES PAID VIA CREDIT CARD. ALL INVOICES OVER $2000 REQUIRE WIRE TRANSFER, CASHIERS CHECK, CASH, OR APPROVED COMPANY CHECK.

PLEASE CONTACT SABRINA @ 209-832-0100 WITH ADDITIONAL PAYMENT QUESTIONS.