Biesse "Rover B 7.40FT-K" CNC Machine - c/w (3) Vacuum pumps  Ended

Ended

2311 Boul des Enterprises Terrebonne, QC Canada J6Y 1W9

- Winning Bid : $25,000.00 CAD Sold

- 105 Bid(s)

- High Bidder: C****c

Biesse FT, 10' NC Slide Saw, Italpresse (Hot) Vitap NC Doweler yr 2021 in Quebec ( Closed #41333123 )

RIGGING ...CALL ALEXANDRE AT 450-656-4160

Two Locations: Please note that (4) Machines will be Loaded out from RANGEMENT PLUS' two Locations (4) from the Terrebonne Location and (4) from the Laval Location.

ALSO UP FOR BID: VITAP BC91 EVO Contour Edgebander yr 2020 * PAOLONI P3200AX NC 10' Sliding Table Saw * ITALPRESSE XL/8-S Press yr 2021 HOT PRESS (Like New) * BIESSE Rover 20 CNC Machine yr 2004...

-

Item Location

2311 Boul des Enterprises Terrebonne, QC Canada J6Y 1W9

-

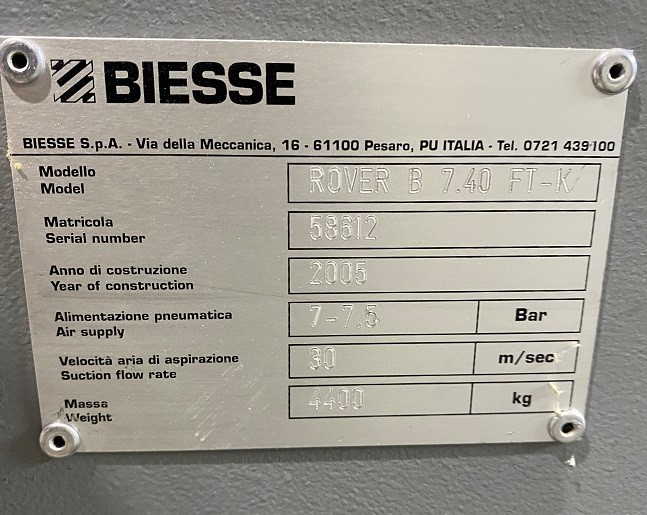

Make

Biesse

-

Model

Rover B 7.40FT-K

-

Serial Number

58612

-

Year

2005

-

Phase

3 PHASE

-

Voltage

575 VOLT

-

Inspection Date

Wed Nov 02 2022 10am-2pm

-

Final Removal Date

Nov 11 2022

-

Estimated Dimensions

See Photo

-

Estimated Weight

7,000 lbs

-

Seller Comment

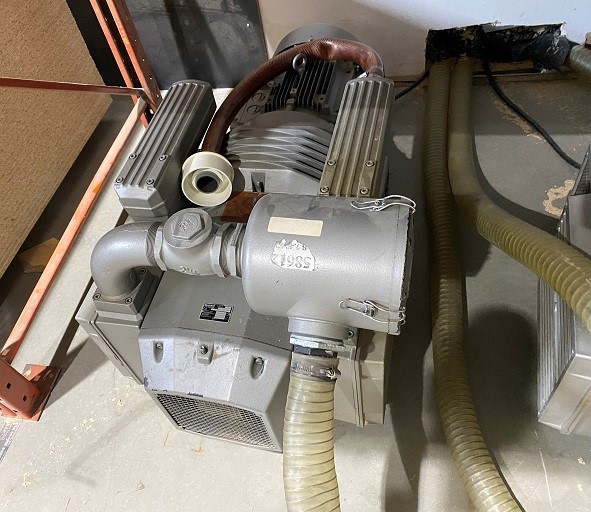

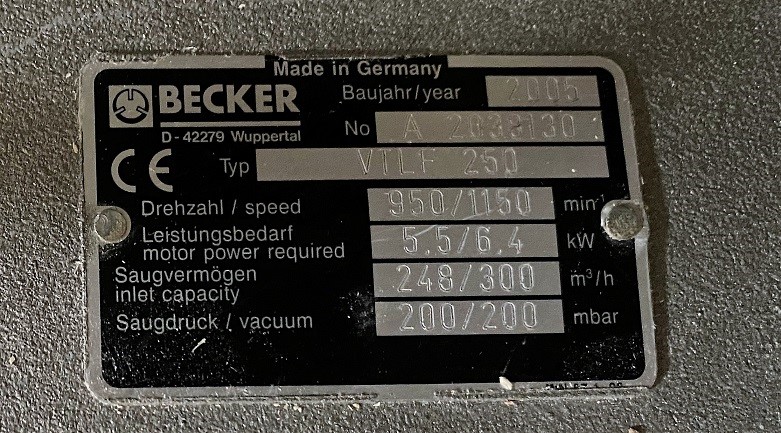

Comes with 3 Vacuum Pumps

-

Load Fee

1800

-

page views

1761

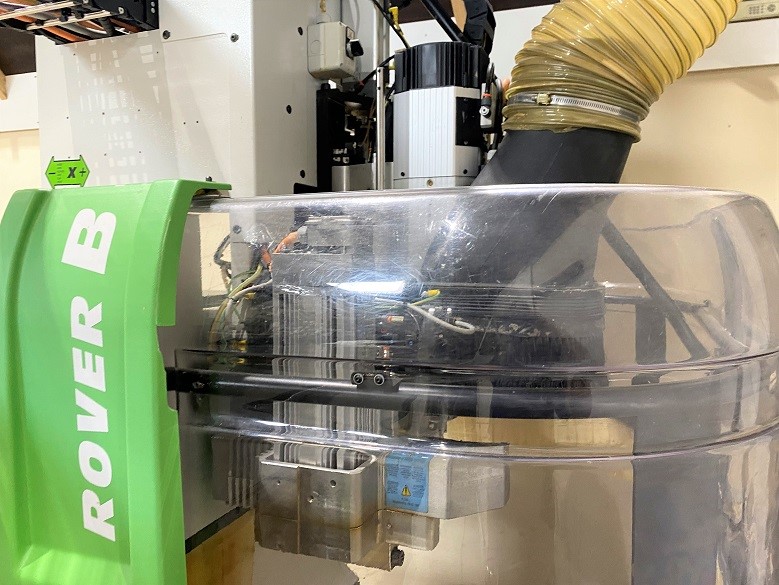

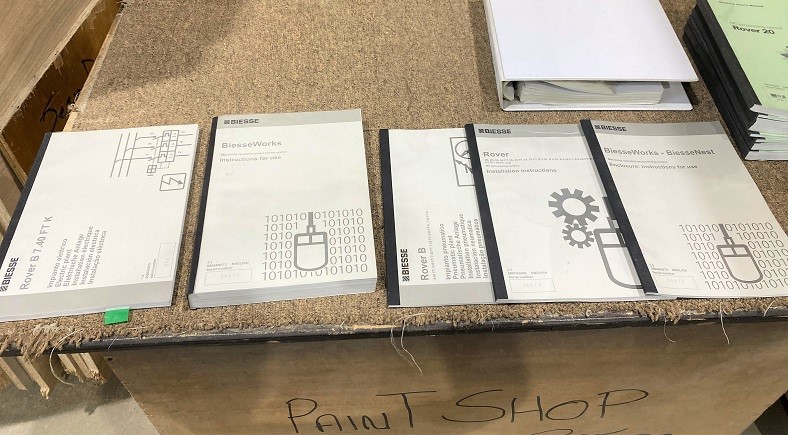

Biesse Rover B 7.40FT-K CNC Machine

Please note: This Machine is Located in Terrebonne, QC (Dock & Ground Level)

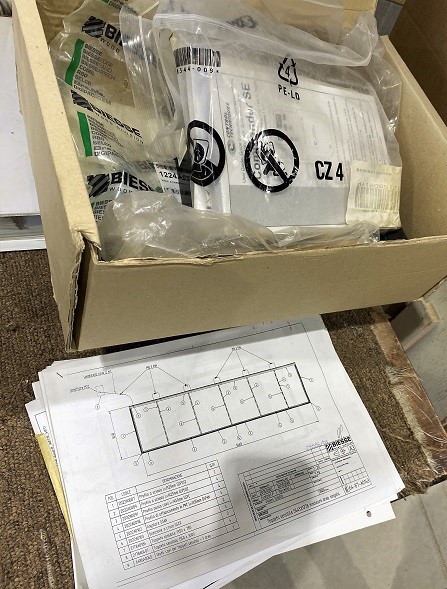

Working cap.: X-Axis is 145" (3,685 mm), Y-axis is 61" (1,550 mm), X-asis working field with all the tools is 145" (3,685 mm), X-axis working field with main spindle is 157" (3,996 mm), Y-axis field with all verticle spindles is 60.6" (1,539.5 mm), Y-axis working field with main spindle is 72.8" (1,850 mm), Z-axis clearance is 7" (180 mm ).

- Programmable speed: X- & Y-Axis is 3,937 IPM and Z-axis is 1,181 IPM.

- Equipped with: (12) Independent vertical boring spindles forming an L-configuration with (6) spindles on the Y-axis & (6) spindles on the X-axis; inverter controlled 2.3 HP spindle motor with 4,000 RPM.

- A total of (6) horizontal spindles provide horizontal boring capabilities on all (4) edges of the panel, (4) on the X-axis (2 in ea. direction) and (2) are paralleled with the Y-axis (1 in ea. direction), X-axis grooving saw.

- Options included: (1) 16.3 HP Vertically mounted HSD Electrospindle, liquid cooled and inverter driven at 1,000 - 24,000 RPM with max. torque from 12,000 - 20,000 RPM.

- "Ride Along" 10-position Automatic tool changer for "on-the-fly" tool changes with HSK-63F tool holders.

- Work area with: Flat table designed for "Nested Base Manufacturing" with (2) independent working areas, (12) external pop-up reference pins with (8) on the back of the table and (2) on the RH side and (2) on the LH side. The unit is prepared for (optional) "quick fit" vacuum outlets for optional clamping of small or irregularly shaped parts.

- Separate control console with: "NC 1000" Controller, MS-Windows based technology, Pentium- CPU, hard drive, CR-ROM reader, mouse, USB ports, parallel port, Serial port, and network card. NC 1000 software for easy programming of boring, routing, and grooving functions.

- Operating system for real-time multitask processing; programs can be transferred via diskette or downloaded by wire; built-in 1,500 W air conditioner for constant temperature & dust-free environment.

- Includes: (3) Vacuum Pumps

- Emergency stop rope & pressure sensitive safety mats that will instantly place machine in "pause cycle" when stepped on and surrounding safety cage; sound absorbing protective head enclosure with debris curtain around bottom edge.

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginUS & CDN CUSTOMS BROKER

COLE INTL (905) 672-6255

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

LOGISTICS DECISIONS - ADAM ( 905) 331-8900

LOCAL FLAT BED TRUCKING QUOTES:

AFFORDABLE TRUCKING - RYAN (647) 866-0056

No information available

CDN FUNDS: THIS AUCTION IS BEING HELD IN CDN FUNDS

PAYMENT: IS REQUIRED WITHIN 48 HRS OF AUCTION ENDING. PLEASE DO NOT MAKE ANY FORM OF PAYMENT UNTIL RECEIVING YOUR INVOICE

PAYABLE METHOD: TO EQUIPMENT AUTHORITY

REMOVAL: AT BUYERS EXPENSE

REMOVAL DEADLINE: NOV 11, 2022

INSPECTION BY APPOINTMENT: WED NOV 02 2022 10am - 2pm

AUCTION END DATE: THUR, NOV 03 2022

BUYER PREMIUM: 15% BUYER PREMIUM SURCHARGE WILL BE ADDED TO ALL LOTS

FONDS CDN : CETTE VENTE AUX ENCHÈRES EST TENUE EN FONDS CDN

PAIEMENT : EST REQUIS DANS LES 48 HEURES SUIVANT LA FIN DE L'ENCHÈRE. VEUILLEZ N'EFFECTUER AUCUNE FORME DE PAIEMENT AVANT D'AVOIR REÇU VOTRE FACTURE

MÉTHODE DE PAIEMENT : À EQUIPMENT AUTHORITY

ENLÈVEMENT : AUX FRAIS DES ACHETEURS

DATE LIMITE DE RETRAIT : 11 NOVEMBRE 2022

INSPECTION SUR RENDEZ-VOUS : MER 02 NOV 2022 10h - 14h

DATE DE FIN DE L'ENCHÈRE : JEU 03 NOV 2022

PRIME DE L'ACHETEUR : UN SUPPLÉMENT DE 15 % POUR LA PRIME DE L'ACHETEUR SERA AJOUTÉ À TOUS LES LOTS