Homag "KL 78/A20/S2" Edgebander - High Speed  Ended

Ended

Complete Manufacturing Facility - Grapevine, TX

- Winning Bid : $5,050.00 USD Sold

- 16 Bid(s)

- High Bidder: b****a

Complete Woodworking Plant Auction - Day 1 of 2 - Grapevine, TX ( Closed #53870216 )

Store fixture manufacturer in Dallas-Ft. Worth, TX metro area is closing one of its plants (former PIN plant) and auctioning all assets. Over 100,000 square foot plant minutes from DFW airport loaded with over 1000 lots. Disa 200 HP dust collector, Holzma beam saws, Homag and Weeke CNC machines, Altendorf sliding table saw, Ligmatech case clamps, Koch CNC bore/dowel machine, Ford delivery van, forklifts, pallet racking, air compressors, raw materials, hardware, office furniture and much more! LOTS BEING ADDED DAILY!

-

Item Location

Grapevine, TX - DFW Airport area

-

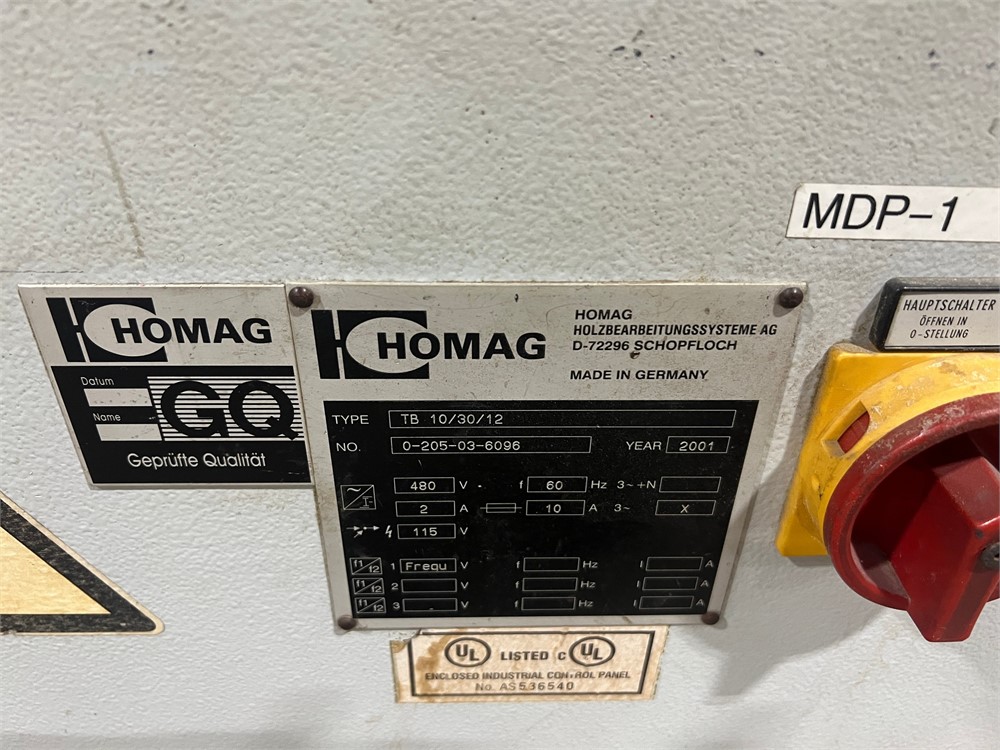

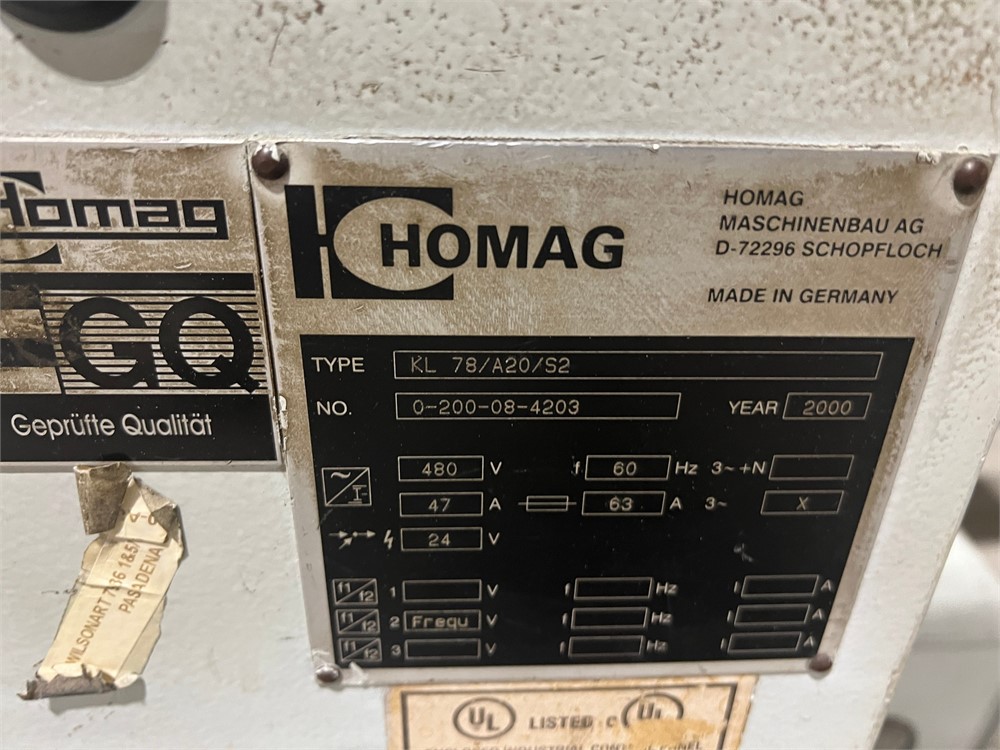

Make

Homag

-

Model

"KL 78/A20/S2"

-

Serial Number

0-200-08-4203

-

Year

2000

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Inspection Date

See Homepage

-

Final Removal Date

See Homepage

-

Estimated Dimensions

22' x 4' x 6.5'

-

Estimated Weight

-

Seller Comment

-

Load Fee

A Rigger is required for this lot. Buyer is responsible for break down & loading.

-

page views

1637

Homag "KL 78/A20/S2" Edgebander - High Speed

0.4 - 20 mm Edge thickness cap., min. panel width 55 mm (2-1/4"), panel thickness 12 - 60 mm, min. edge length 7.8"

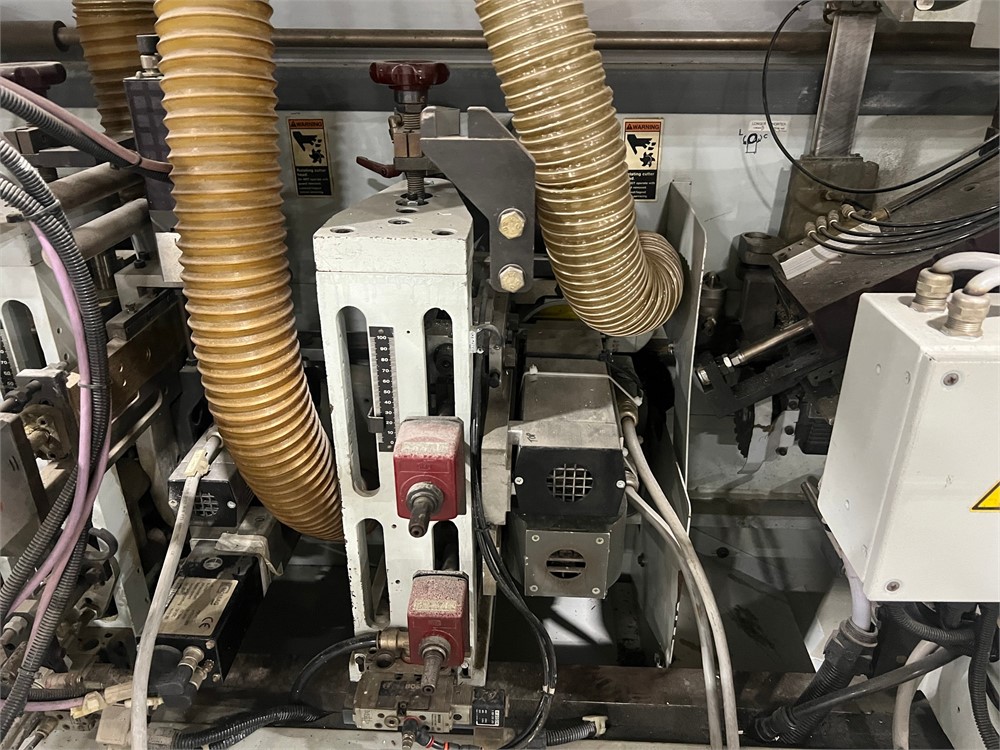

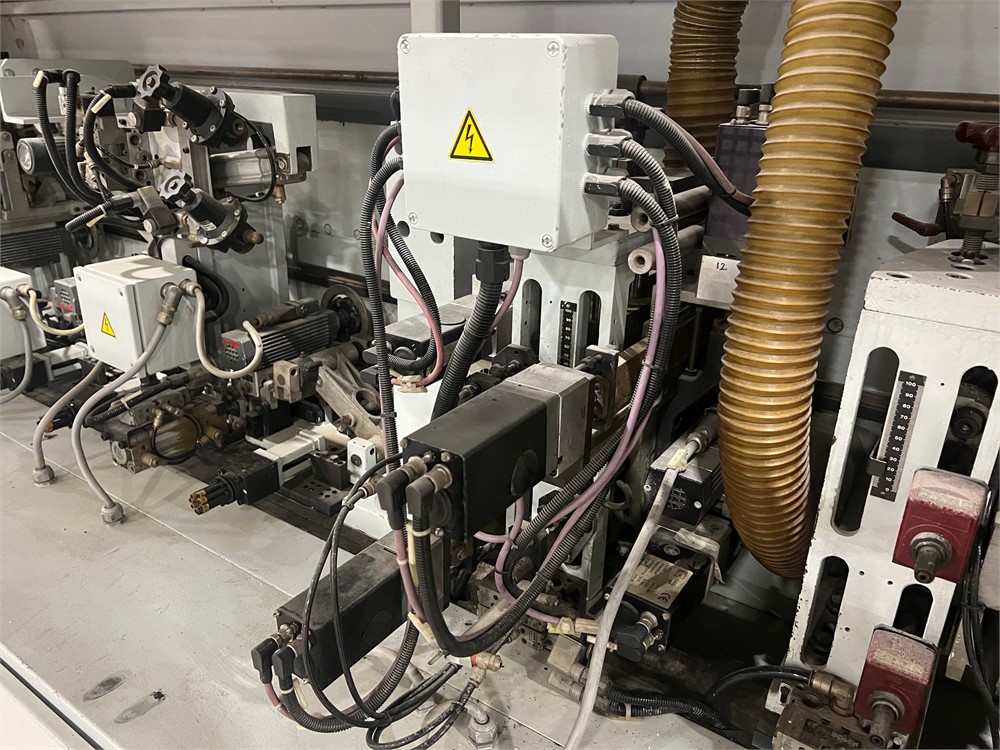

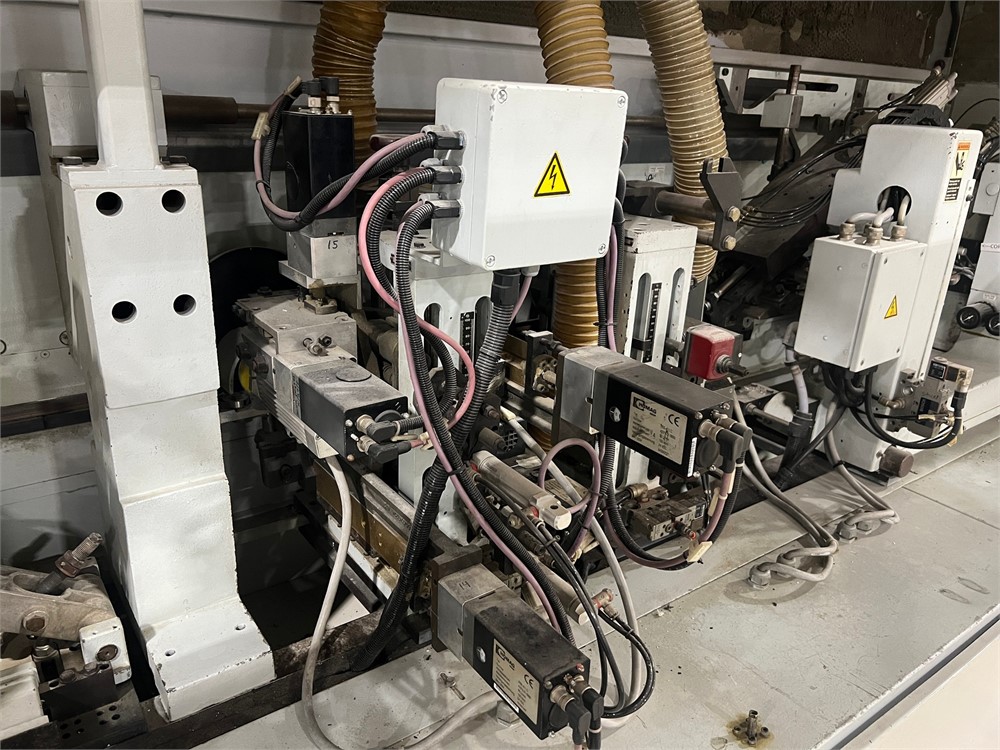

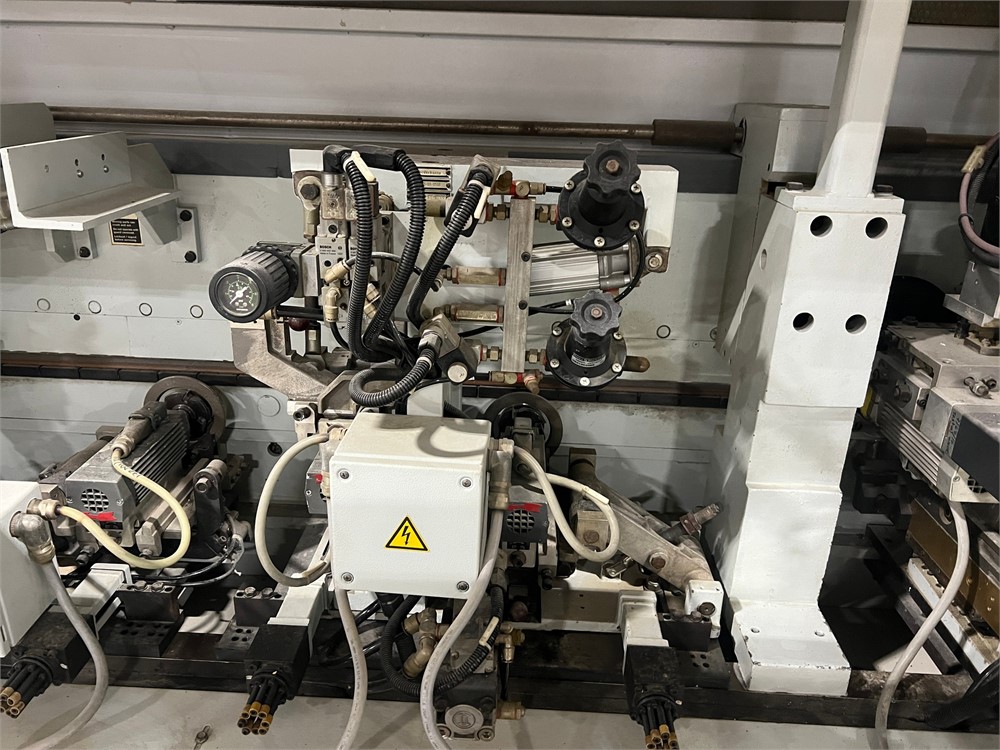

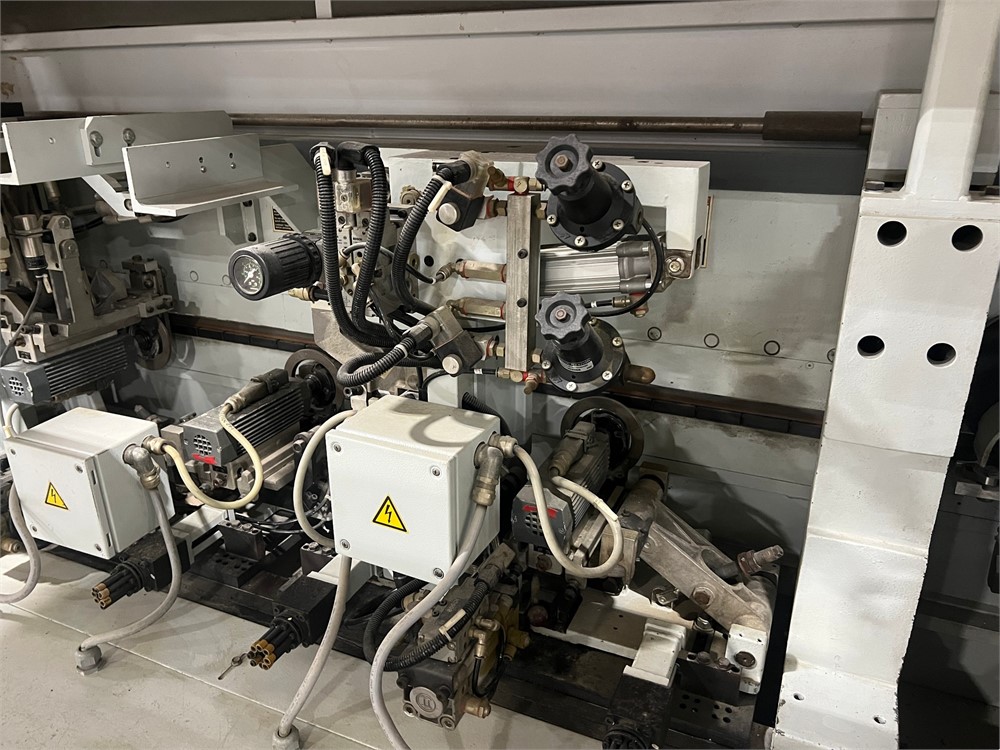

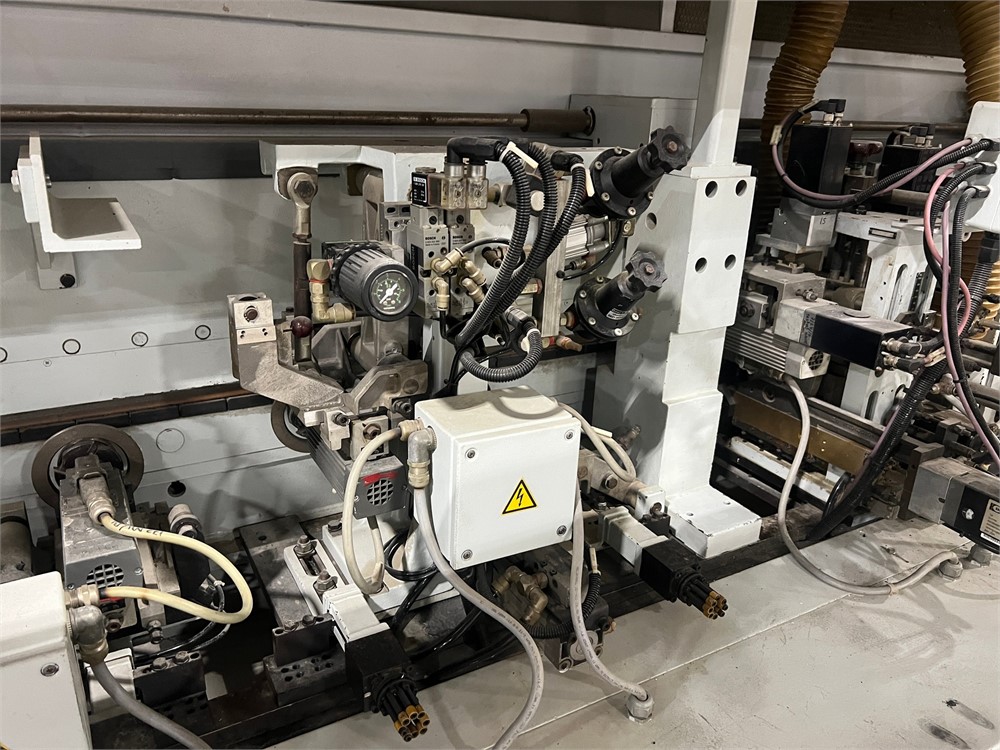

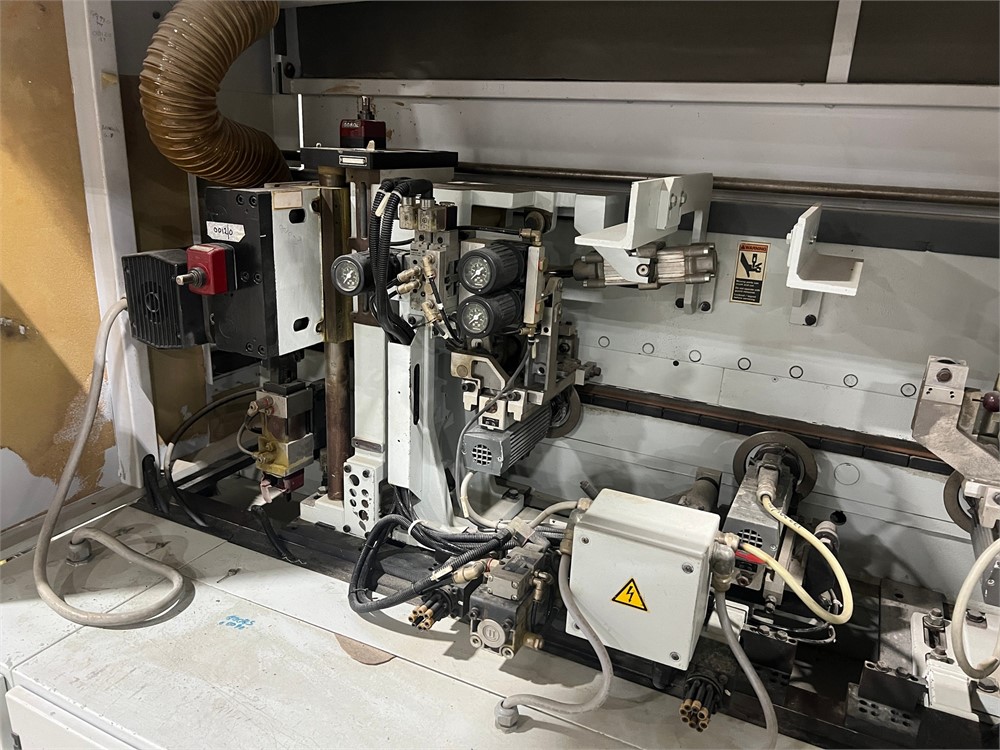

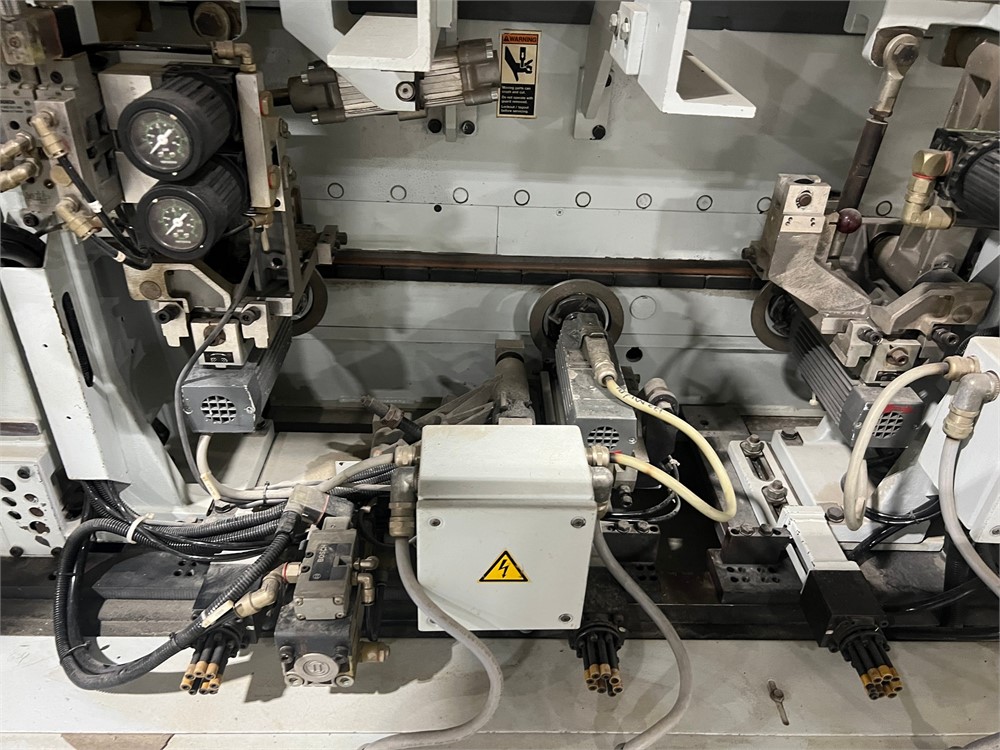

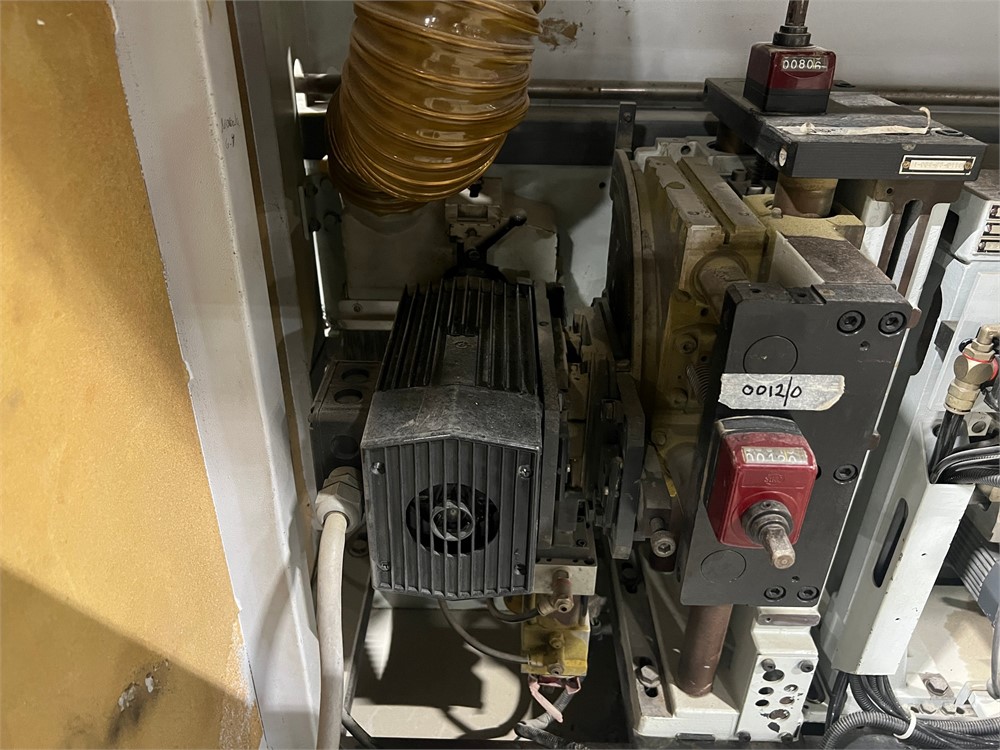

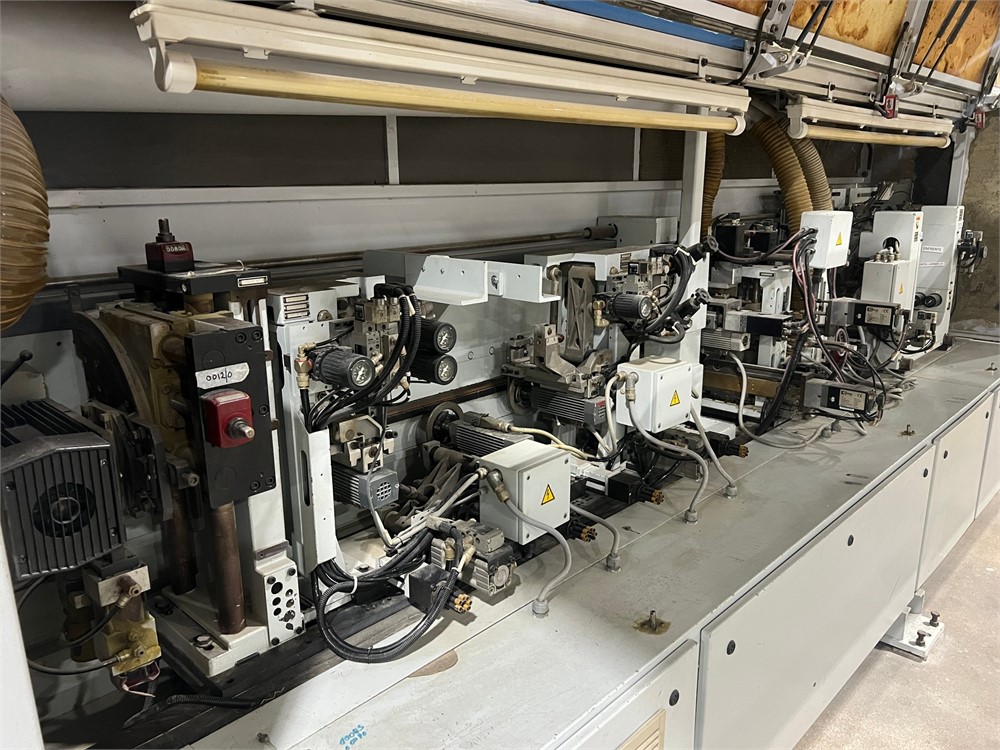

Stations Include: Premill w/ Servo Fence, Pneumatic 7 Pressure Rollers, End Trims, Top/Bottom Trim Hog, Top/Bottom Trim Profile w/ Servos, 4 Motor Corner Rounder, Radius scrapers, Hot air blowers, Buffers.

(2) Pre-milling heads (each with 3 kW - 6,000 RPM motor, one with jump control); chip blowoff unit after last head; SIKO digitals for horizontal & turret for vertical adjustments; pre-heating infeed fence (for panel edge).

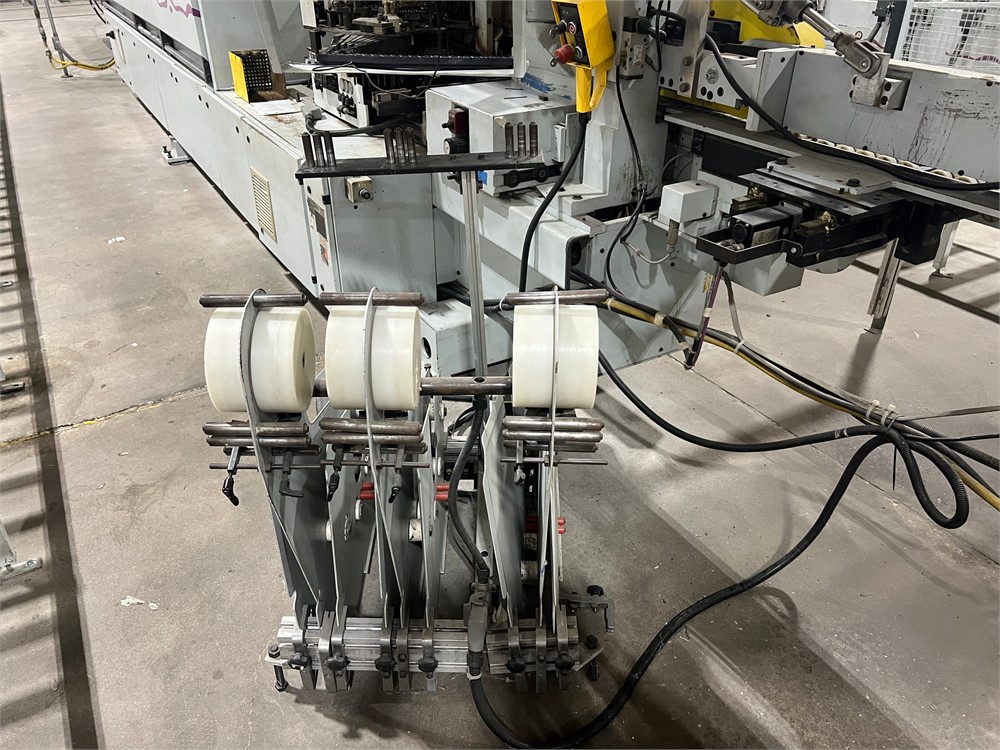

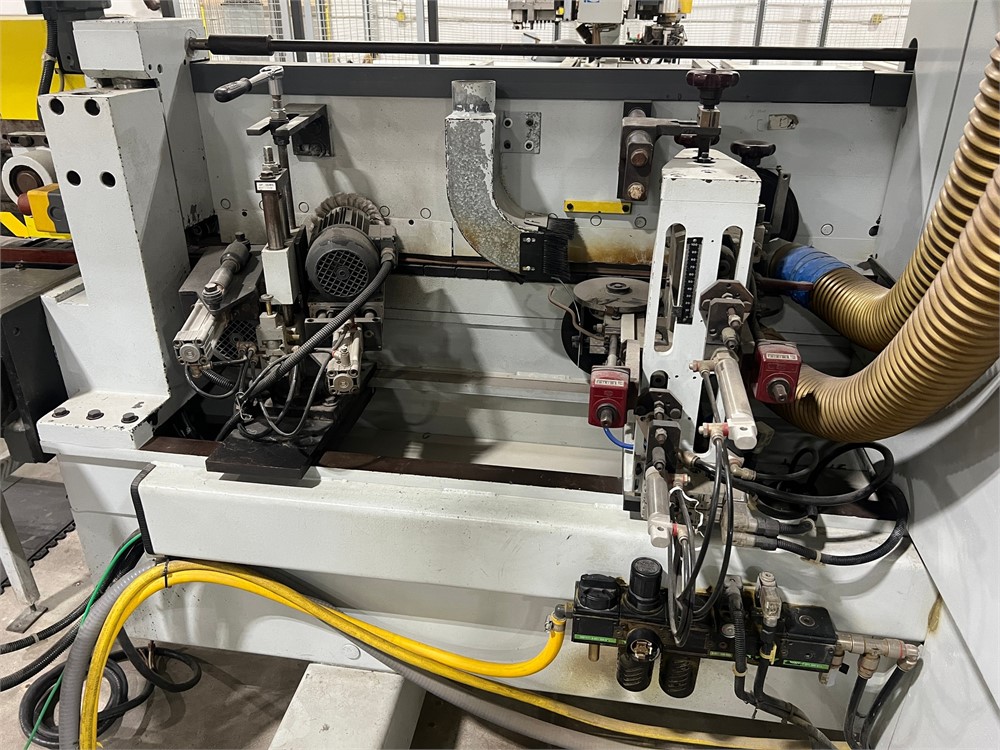

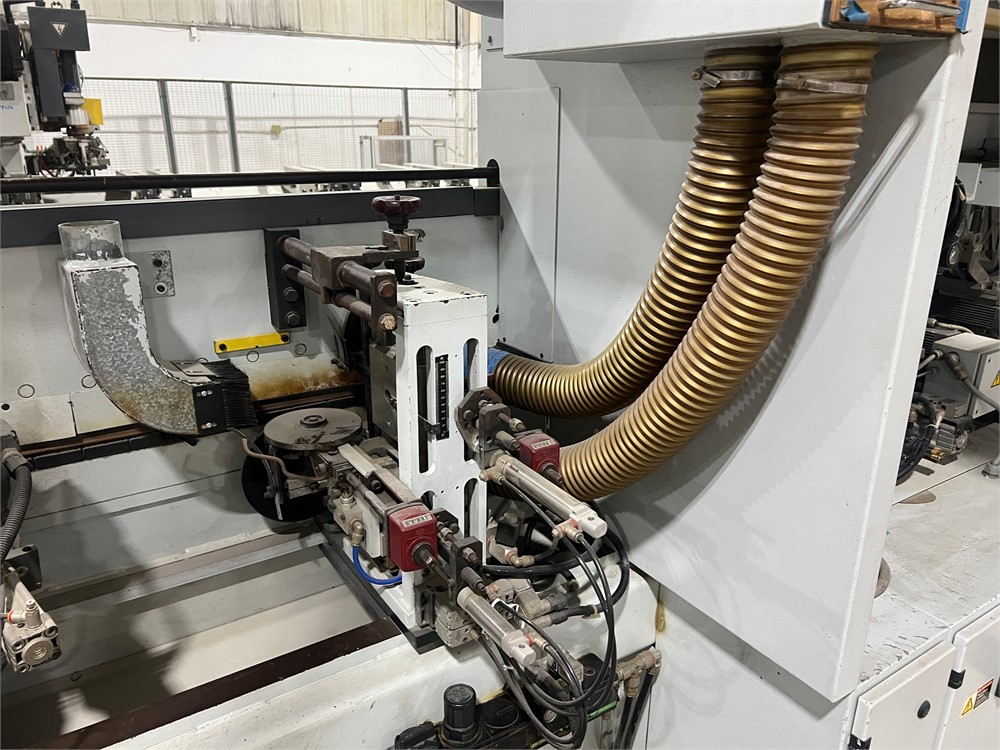

Automatic multiple coil feed magazines for coil material up to 3 mm thickness, strip feed magazine for up to 20 mm (3/4") solid wood banding.

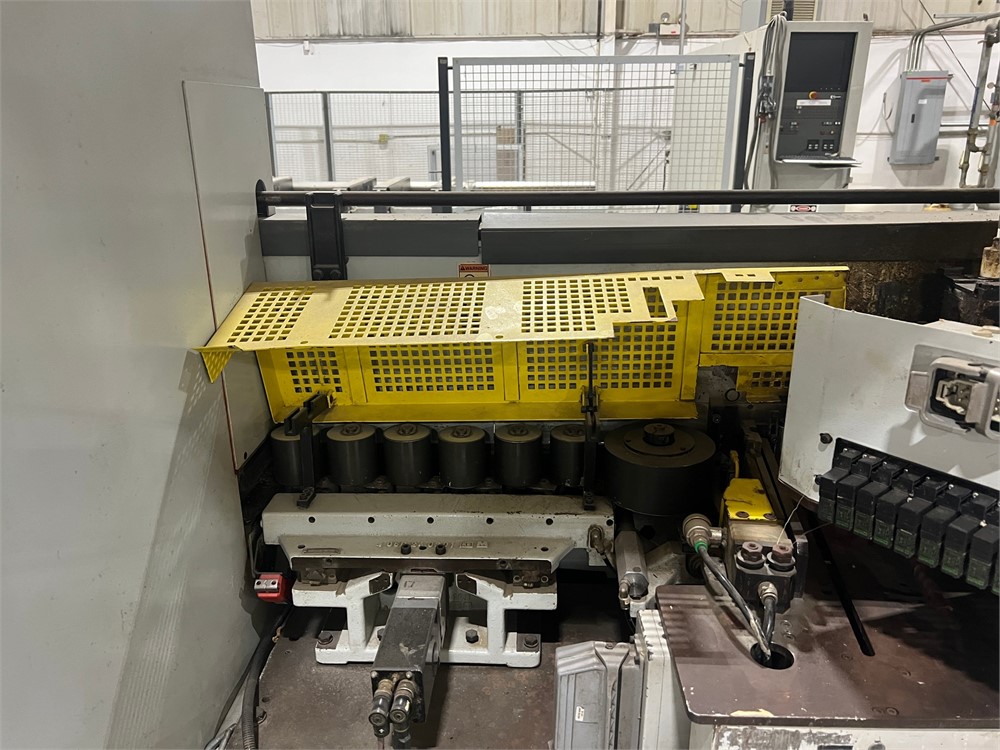

"Quick Melt" glue system "QA 34" with per melt hopper feeder & roller applicator (reversible); pneumatic pressure roll section with (1) large dia. driven & (6) idle rollers.

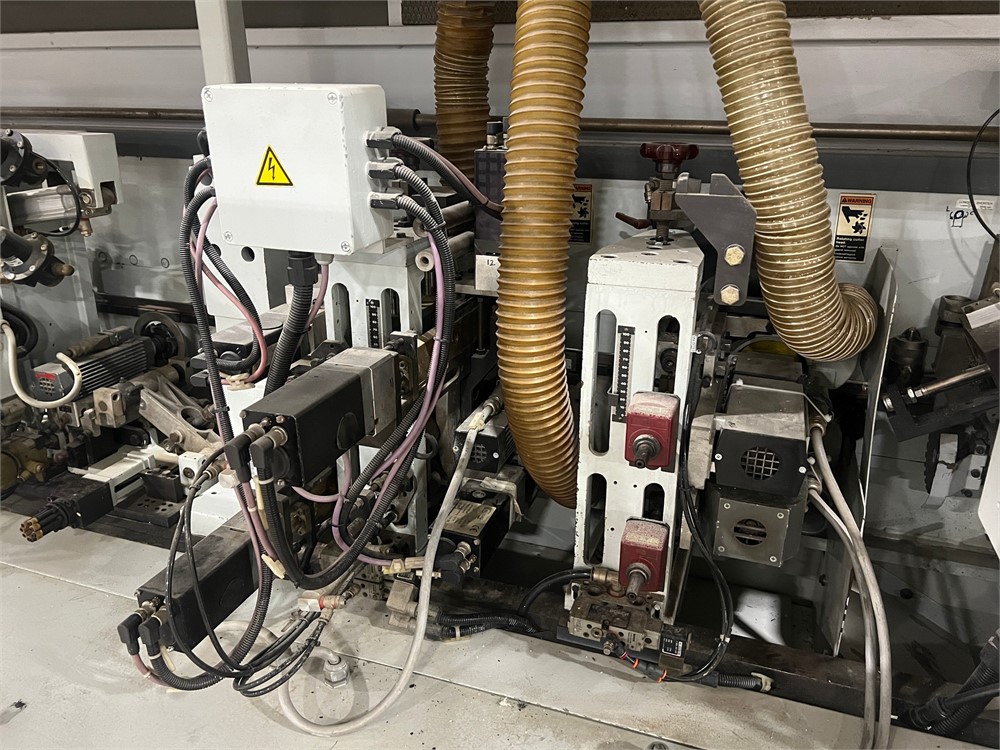

Double motor front & rear end trim (0.7 HP - 12,000 RPM motor ea.), pneumatic chamfer setting.

Top & bottom rough trims (2 HP - 12,000 RPM motor ea.).

Top & bottom bevel & radius trims (0.6 HP - 12,000 RPM motor ea.), tiltable 0° - 30°; pneumatic exclusion from operator panel.

Top & bottom profile trim units for leading & trailing edge (four 0.6 HP - 12,000 RPM motors), up to 4 mm edge thickness (all trim station motors are 200 Cy HF and equipped w/electronic brakes).

Profile tracing from top, bottom and side for chamfering or rounding of pre-trimmed PVC edges; pneumatically controlled blowing nozzles; max. edge thickness 3 mm (1/8"), panel thickness 12 mm to 60 mm (15/32" to 2-3/8"); unit laterally adjustable by max. 50 mm (1-31/32"); collection box for PVC shavings; height adjustment with top pressure beam without tools; manually adjustable with digital mechanical counters.

Top & bottom buffing unit w/oscillation control (0.3 HP - 1,650 RPM motors).

Motorized top pressure beam with powered V-belt holddown, 80 mm wide Heavy Duty feed chain w/rubber pads, automatic chain track lubrication system, 5 HP feed drive for variable feed speed of 23 - 98 FPM.

Line control with HOMATIC "NC 21" controller features: Real-time "OS9" operating system, functions in Windows environment; PLC w/storage for (40) working programs, each with (160) functions for remote control of processing units; keypad w/LCD display, fault diagnostic, etc.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (3% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice. Applicable State & local tax will be added in.