Ott "Atlantic AV12" Edgebander  Ended

Ended

Kitchen Cabinet Shop machinery auction- Farmingdale, NY

- Starting Bid : $250.00 USD

- 0 Bid(s)

Kitchen Cabinet Shop Woodworking Machinery Auction - Farmingdale, NY ( Closed #54771581 )

After 30 Years, Glissade New York, LLC will be moving to a different location and auctioning all of its woodworking machinery no longer required for continuing operations. Machinery includes, Yates Maerican Double Spindle Shaper with TWO Powerfeeders, Biesse Rover 20 CNC Router, Mereen Johnson 424-DC Straight Line Rip saw, Black Bros Glue spreader, C.R. Onsrud Pin Router, and much more!

-

Item Location

399 Smith St, Farmingdale, NY 11735

-

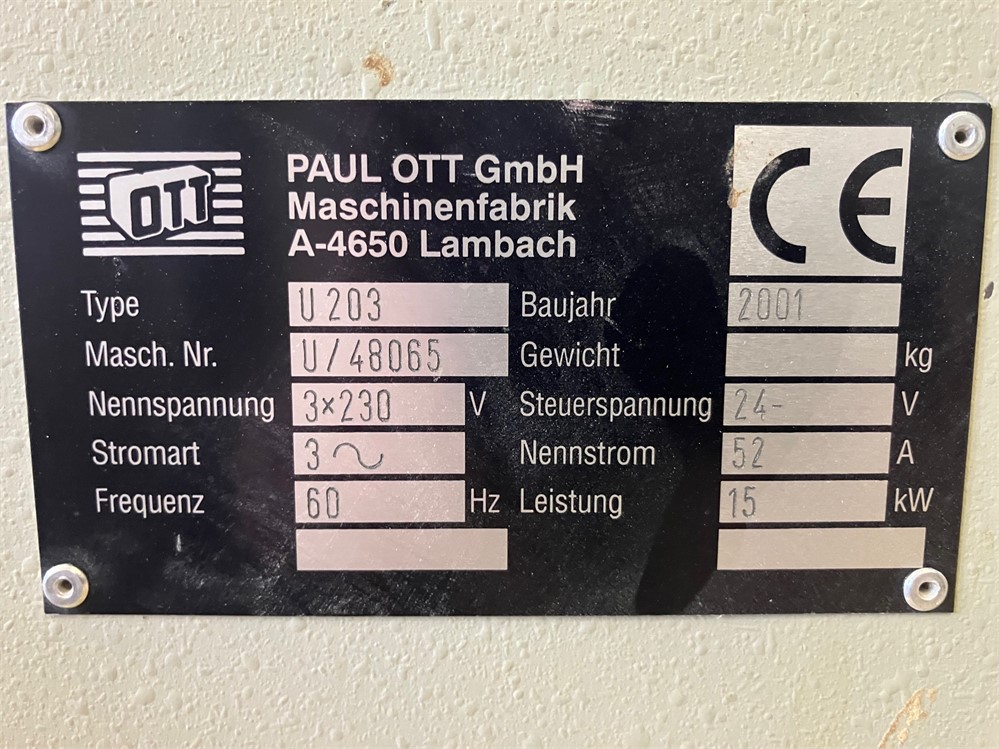

Make

Ott

-

Model

AV12

-

Serial Number

U48065

-

Year

2001

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

August 21st - September 5th, 2023 By appointment only

-

Final Removal Date

September 5th - September 12th, 2023 By appointment only

-

Estimated Dimensions

160" L x 48" W x 60" H

-

Estimated Weight

3,500 Pounds

-

Seller Comment

Buyer responsable for load out

-

Load Fee

N/A

-

page views

590

Ott "Atlantic AV12" Edgebander

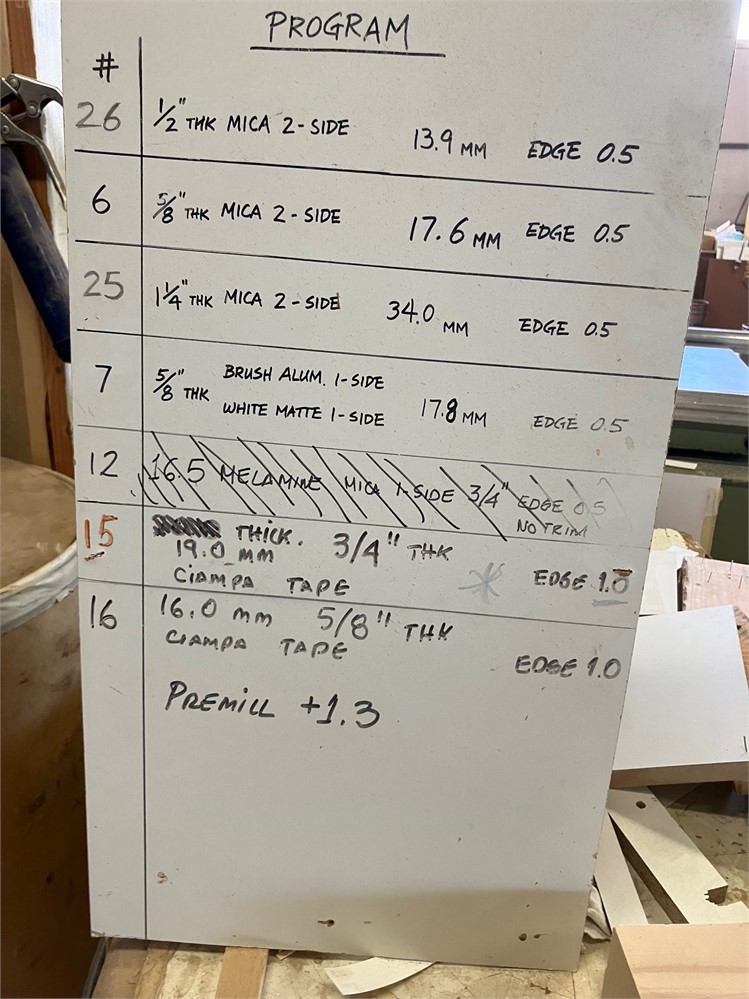

10mm Cap. edge banding thickness and 42 mm (1-5/8") in height; 70 mm min. panel width and 150 mm min. length; programmable PLC control unit to program & set machine functions for automatic recall & operation.

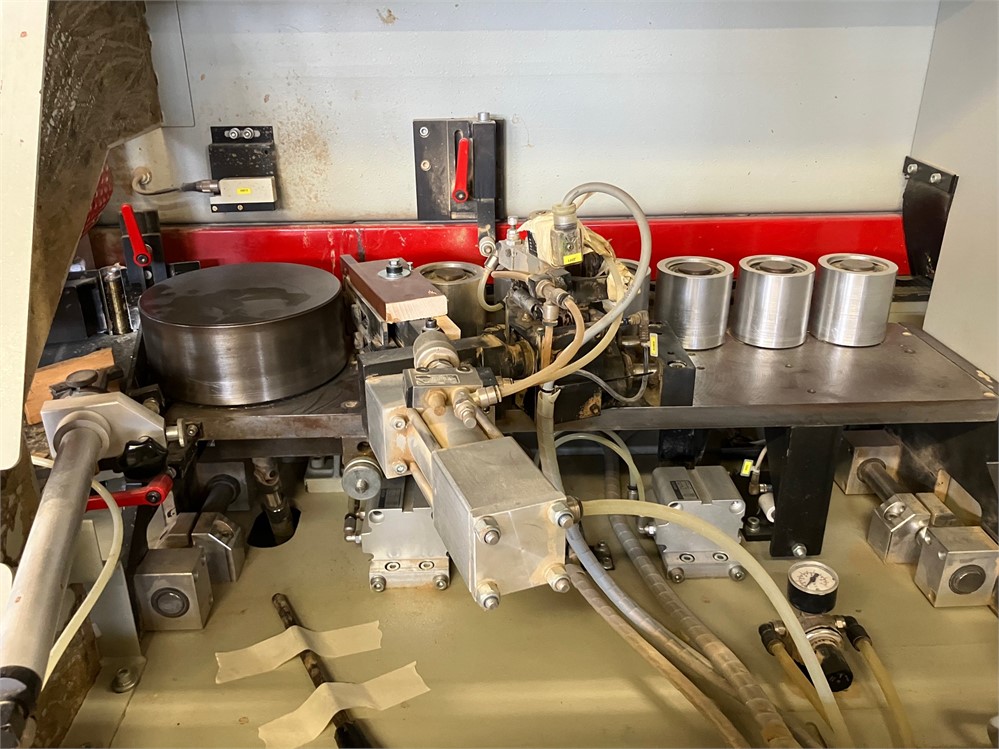

Automatic strip & coil feed magazine with 4 mm PVC guillotine (6" pack cap. for strips), PLC controlled "Quick Melt" (5 - 6 Min heat-up) Teflon coated Hot Melt glue pot (top mounted), 1" dia. glue applicator roller, reversible rotation by flip of switch; pressure section with (1) large dia. clutch controlled drive roller and (3) smaller, pneumatic pressure idle rollers w/automatic setting for edge thickness.

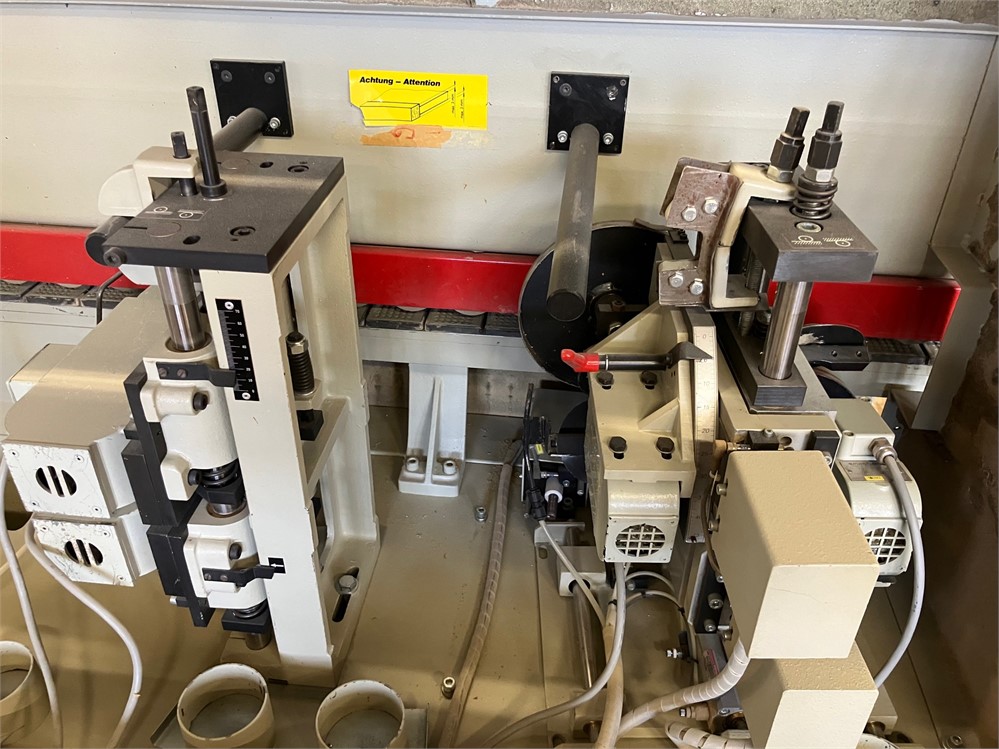

Front & rear end trims (motors 0.4 HP - 12,000 RPM ea.), adjustment possible 0° - 3° bevel cutting.

Top & bottom rough trims (motors 1 HP - 12,000 RPM ea.), fine adjustment for guide rollers; Top & bottom fine/bevel & radius trim (motors 0.4 HP - 12,000 RPM ea.), tilt 0° - 45°, fine adj. for guide rollers & side feeler shoes (incl. 2nd set of motors for "quick change" to interchange from bevel to radius trim).

Top & bottom buffing - Oscillating

All workstations are mounted on (2) hardened steel shafts, mobile and positioned by air cylinders controlled by the PLC unit. Feed chain with 80 mm wide rubber pads, feed speed of 12Mmin with 3 HP drive.

Sound enclosure w/large windows, central dust collection for all stations built into machine bed, operator control panel w/electronic PLC control unit

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

Login| If a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). |

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.