Shaw Almex "TL-6-4-9" Thermoforming Membrane Press  Ended

Ended

Items located in Kansas City metro

- Winning Bid : $750.00 USD Sold

- 10 Bid(s)

- High Bidder: f****1

DMC 4 head widebelt & Almex membrane press - Kansas City, MO ( Closed #54913308 )

Cabinet shop in KC metro is offering these 2 machines they do not use for their current production.

-

Item Location

1308 W 9th Kansas City, MO 64101

-

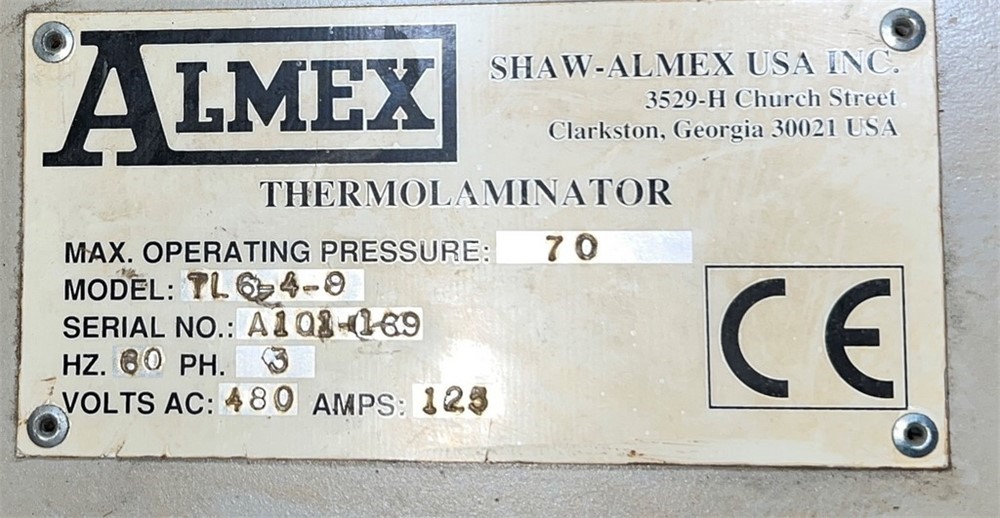

Make

Shaw Almex

-

Model

TL-6-4-9

-

Serial Number

A101-169

-

Year

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Inspection Date

See main page for inspection information.

-

Final Removal Date

See main page for loading dates

-

Estimated Dimensions

96" x 144" x 102" Mahine only size

-

Estimated Weight

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

page views

1318

Thermo-Laminating Press, membrane or "membraneless" operation for vinyl, heat transfer foils & veneer products; by the flip of a switch at the control console it changes from membrane to membraneless pressing. It uses "high volume" air pressure and a powerful instant vacuum creating suction and pressure at the same time.

Works without hydraulic cylinders: A platen size rubber pressure air bag under the lower platen (bolster) inflates and can withstand pressure up to 200 PSI; by in- & deflating it opens-and-closes the Press; a 240-gal. air tank supports the in/out high volume air movement.

The vacuum that sucks down the overlay to the substrate is generated by a 5 HP vacuum pump and supported by 240-gal. vacuum tank for instant vacuum power.

Double shuttle tray system, each tray 46" x 100" x 1-1/4" deep, they shuttle in-and-out of press on track guided casters for loading-and-unloading.

54" x 108" Aluminum top platen with a standard 3 mm thick silicone membrane (currently not being used); a small vacuum is used to draw the membrane up against the upper heated platten.

46" x 100" Max. part size for full wrap, 2" max. part thickness and a 2-1/4" max. chamber height; 84 PSI max. laminating pressure.

Top platen & infeed lower tray (platen): Both with resistance silicone heater elements, 150° - 350° F max. temperature with infinite control, 21 kW heating elements in each platen.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available