Homag "BOF 712/48/13/R" CNC Flat Table Router - Twin Table  Ended

Ended

Complete Manufacturing Facility - Grapevine, TX

- Winning Bid : $250.00 USD Sold

- 1 Bid(s)

- High Bidder: j****s

Complete Woodworking Plant Auction - Day 2 of 2 - Grapevine, TX ( Closed #54724790 )

Store fixture manufacturer in Dallas-Ft. Worth, TX metro area is closing one of its plants (former PIN plant) and auctioning all assets. Over 100,000 square foot plant minutes from DFW airport loaded with over 1000 lots. Day 2 consists of: Homag Edgebander, Forklifts, Store Fixtures, Hardware, Lift Tables, Return Conveyors, Plus Much More!

-

Item Location

Grapevine, TX - DFW Airport area

-

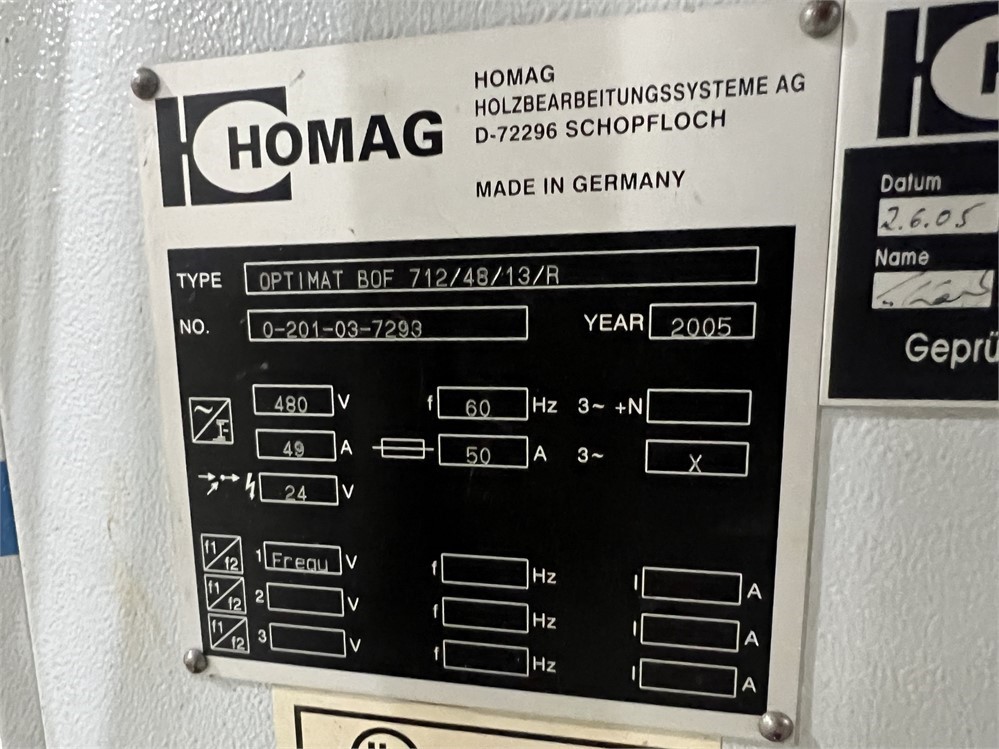

Make

Homag

-

Model

"BOF 712/48/13/R"

-

Serial Number

0-201-03-7293

-

Year

2005

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Inspection Date

See Homepage

-

Final Removal Date

see Homepage

-

Estimated Dimensions

35' x 17' x 10'

-

Estimated Weight

-

Seller Comment

-

Load Fee

A Rigger is required for this lot. Buyer is responsible for break down & loading.

-

page views

201

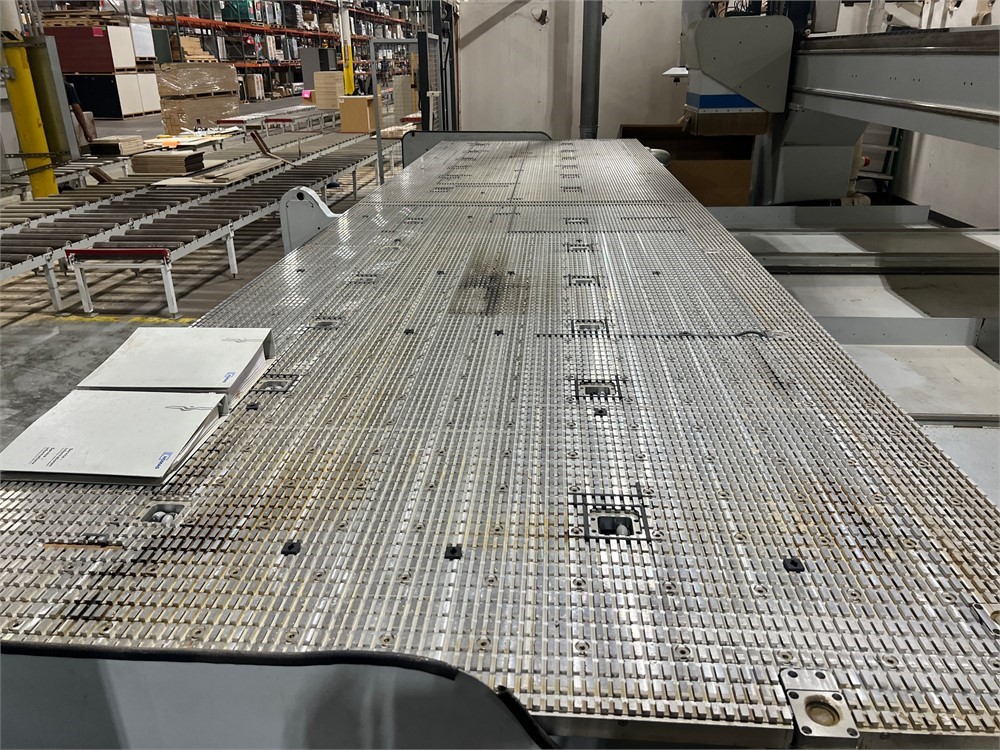

Homag "BOF 712/48/13/R" CNC Flat Table Router - Twin Table

(2) 10' x 5' (120" x 62") Twin Moving Tables can operate independently for unloading/loading on one table while the other is in process, or together as one large 20' x 5' work area.

Max. workpiece:

- Length 204" (alligned with table edges), 195" alligned with stop pins, or 120" on each table alligned with table edges.

- Width 60" alligned with table edges and 51" alligned with front stop pins, 8-1/4" max. part height.

Working Areas:

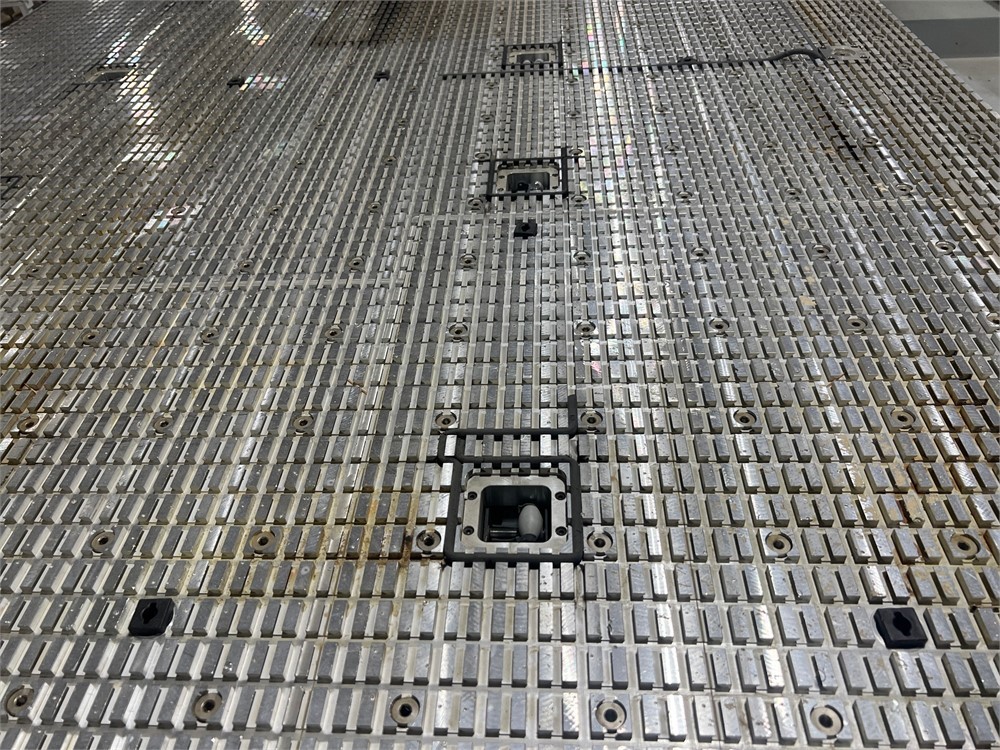

- Cross grooved aluminum "Alu-Matrix" tables work equally well for flat table (nested base) or pod fixturing, and include pop-up rollers to move material on/off quickly.

- Like the tables, the (2) spindle head carriers have independent cross bridge and up/down servo control, which facilitates slaved part cutting.

- Each spindle/drill combination can perform separate processes on the same piece simultaneously, or the cutting of completely different part programs simultaeously; in other words "THE MAXIMUM PROCESSING FLEXIBILITY"!

Boring Units:

- (2) 12-spindle, independentvertical boring units with 7-spindles in "X" axis & 6-spindles in "Y" axis.

- The (2) spindle/drill combinations are mounted on separate head carriers with independent cross bridge and up/down servo control as described above.

Machining:

- (1) 19.4 HP, HSK-63F, liquid cooled routing spindles, variable speed from 0 - 24,000 RPM (constant torque from 0 - 12,000 RPM), (2) 12-positionATC tool carousels,

Operator & Machine Control:

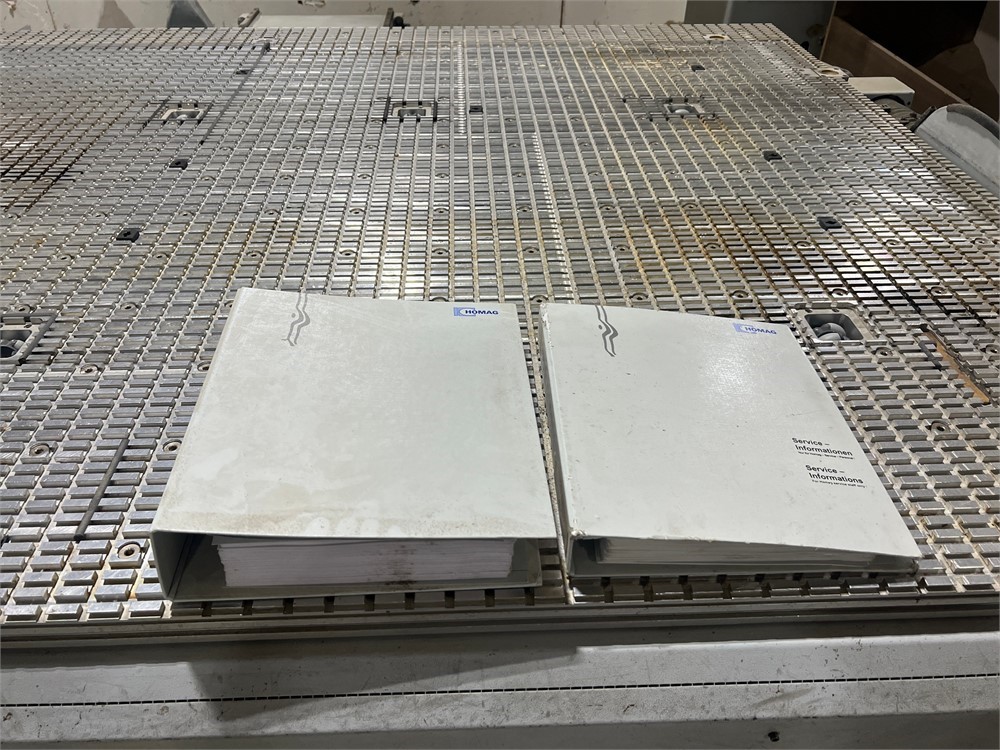

- HOMATIC PC85 WINDOWS XP operating system, flat panel color monitor, keyboard, mouse, (1) hard disk solidly installed, (1) hard disc tor data securing dada, ethernet network connectivity.

- The system includes "WoodWOP" processsing software, WoodSCOUT diagnostic software, barcode scanning software, remote diagnostics, and Intelligent Process Optimization (IPO) software.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (3% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice. Applicable State & local tax will be added in.