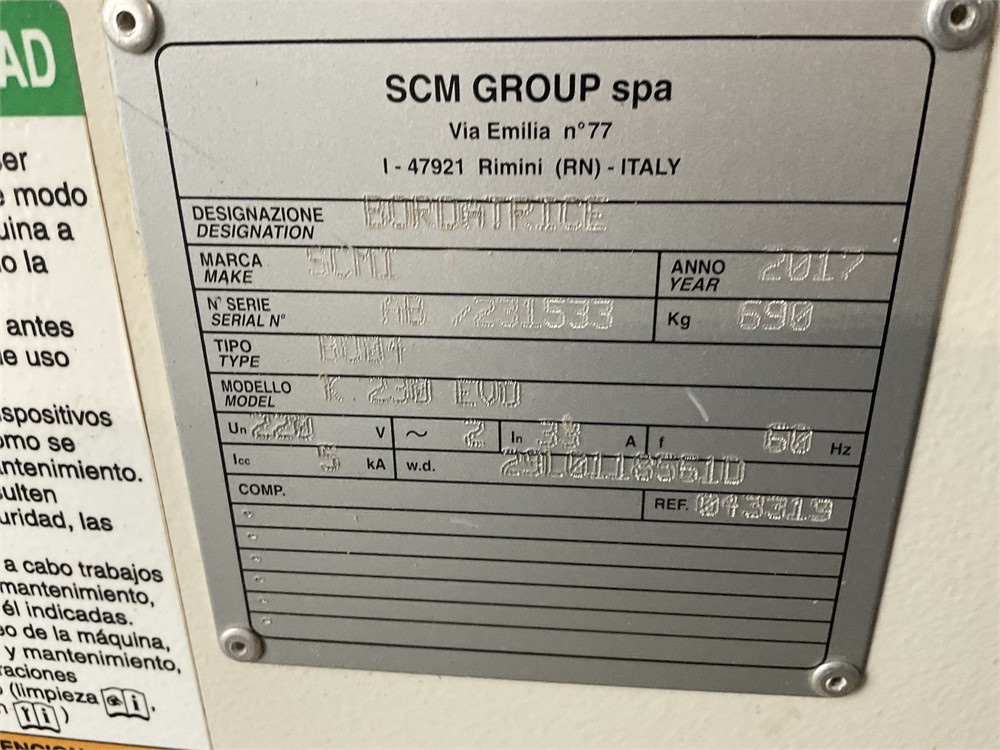

SCM "K230 EVO" Edgebander (2017)  Ended

Ended

Warehouse Auction - Salt Lake City, UT

Salt Lake City, UT

- Winning Bid : $7,000.00 USD Sold

- 31 Bid(s)

- High Bidder: W****y

Warehouse Auction - Salt Lake City, UT ( Closed #56144554 )

Nice selection of woodworking machinery featuring: Biesse Akron 435 Edgebader, Biesse Rover B 4.35FT CNC router, SCM S520 Planer, Plus Much More

-

Item Location

Salt Lake City, UT

-

Make

SCM

-

Model

K230EVO

-

Serial Number

AB/231533

-

Year

2017

-

Phase

1 PHASE

-

Voltage

220 VOLT

-

Inspection Date

By Appt Only Contact Sabrina Burns 209-839-7707 [email protected]

-

Final Removal Date

September 29, 2023

-

Estimated Dimensions

125x42x58

-

Estimated Weight

1600LBS

-

Seller Comment

-

Load Fee

$50

-

page views

343

2017 SCM Group K230E-Evo just recently removed from service and was in full operational condition.

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 3mm.

Machine Base

The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy.

Pressure Beam

All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has digital height indicators and a double row of pressure rollers with steel bearings.

Capacities and Speed

- Edgebanding thickness: .4mm - 3mm (.016-1/8”)

- Guillotine capacity: 3.0mm

- Feed speed: 30 ft/min.

- Panel height: 3/8” min – 1 15/16” max

- Minimum panel length: 5 1/2”

- Minimum panel width: 2 3/8”

- Minimum distance between panels: 22”

Glue Station

Teflon coated glue pot to facilitate glue changeover. Warm up time is approximately eight to ten minutes.

Pressure Section And Automatic Strip Magazine

There are a total of two spring loaded pressure rollers for pressing the banding to the work piece edge. The first roller is Teflon coated. Positioning of the pressure section is determined by a mechanical digital readout. The machine comes equipped with an automatic strip magazine for feeding wood and laminate strips.

Control Panel

The K 230E is equipped with an Orion 1 Plus controller, fixed, located at the infeed of the machine. It is capable of operating all the work units via soft touch buttons, it pneumatically tilt’s the end trim unit from the control panel, it eliminates the use of micro switches, as well as control the temperature of the glue. It is tilted slightly upward for a more ergonomically friendly position for the operator.

End Trimming Station

This unit is composed of two independent .25 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with pneumatic positioning of the unit from the control panel with two preset positions. The unit is also equipped with the “radius” edge feature that rounds over the vertical edge on the corners of a 3mm panel.

Edge Trimming Station

This unit is composed of two independent .5 hp motors operating at 12,000 rpm. The unit is equipped with a combination cutter that allows the operator to manually go from solid wood, to thin material, to a radius, all with the same cutter. All adjustments are carried out with mechanical digital readouts. The unit has top and bottom copy wheels and side copy shoes. The motors have quick release plugs to facilitate tooling changes.

Profile Scraping Unit

Scraping station designed to remove knife marks from thick PVC. The unit is equipped with top and bottom copy wheel and side copy wheels, adjustments are made via mechanical digital readouts. The unit is positioned manually. The unit is also equipped with dust extraction and a collection bin.

Buffing Unit

The buffing unit has two .25 hp motors. It can also be tilted up to 12 degrees to provide a softer, more refined edge finish.

Acoustical Safety Enclosure

All working units are enclosed under an acoustical safety hood to reduce noise and prevent accidents. The hood has a safety microswitch which prevents the machine from operating when the hood is open.

Centralized Dust Extraction

Two 2” dust ports and one 3” dust port for extraction.

Technical Specifications

|

Glue Pot Unit: |

|

|

Heating Time |

Approx. 8-10 min. |

|

Glue Capacity |

2.2 lbs. |

|

End Cutting Trimming Station: |

|

|

Horsepower |

.50 HP |

|

RPM / Tilt |

12,000 RPM / 0-15 degrees |

|

Edge Trimming Unit: |

|

|

Horsepower |

.50 HP |

|

RPM |

12,000 RPM |

|

Tilting |

Combination Cutter for Radius, solid and thin Tape |

|

Scraping Unit: |

|

|

Knife Radius |

3mm |

|

Buffing Unit: |

|

|

Horsepower |

.25 HP |

|

RPM |

3,000 RPM |

|

Diameter/Bore |

152mm/17mm |

|

Feed Motor Horsepower |

1 HP |

|

Feed Speed |

30 FPM |

|

Frequency Converter |

200 Hz |

|

Dust Hood Diameter |

2 @ 2” and 1 @ 3” and 1 @ 4” |

|

Pneumatic Operating Pressure |

90 PSI |

|

Weight: |

699 kg/ Roughly 1600 lbs. |

|

Electrical Requirements: |

35 amps @ 220v single phase |

|

Dust Requirements: |

1,000 cfm |

|

Dimensions (LxWxH): |

125” x 42” x 58” |

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available