Doucet "Feedback 36" Shape and Sand Return Conveyor  Ended

Ended

Woodworking Machine Auction - Kemp TX

Kemp TX

- Winning Bid : $2,150.00 USD Sold

- 14 Bid(s)

- High Bidder: t****b

SCM Pratix CNC, Doucet Return, Disa Dust Collector - Kemp, TX ( Closed #59066134 )

Assets no longer required for cabinet manufacturer in the Dallas, TX metro area.

-

Item Location

12521 FM 1895, Kemp TX 75143

-

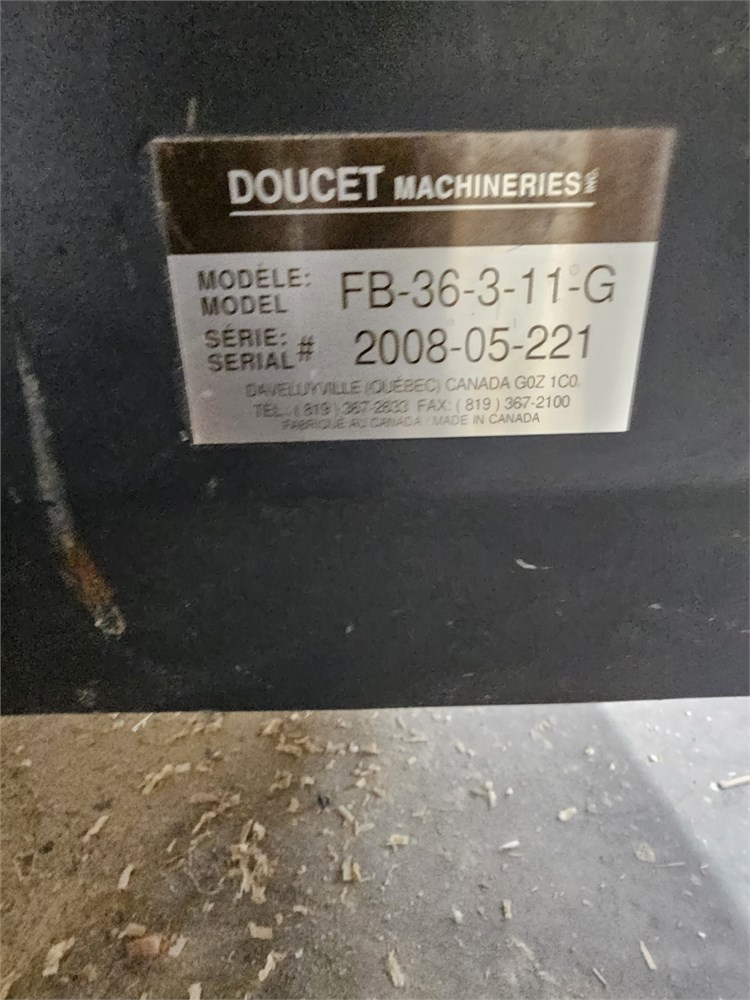

Make

Doucet Machines

-

Model

Feedback 36 FB36-3-11-G

-

Serial Number

2008-05-221

-

Year

2008

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Inspection Date

By Appointment only - please contact Kirk @ 925-250-8248 - [email protected]

-

Final Removal Date

December 13th, 2023

-

Estimated Dimensions

See photos and description

-

Estimated Weight

See photos and description

-

Seller Comment

-

Load Fee

$300 Load Fee

-

Lot Notes

-

page views

114

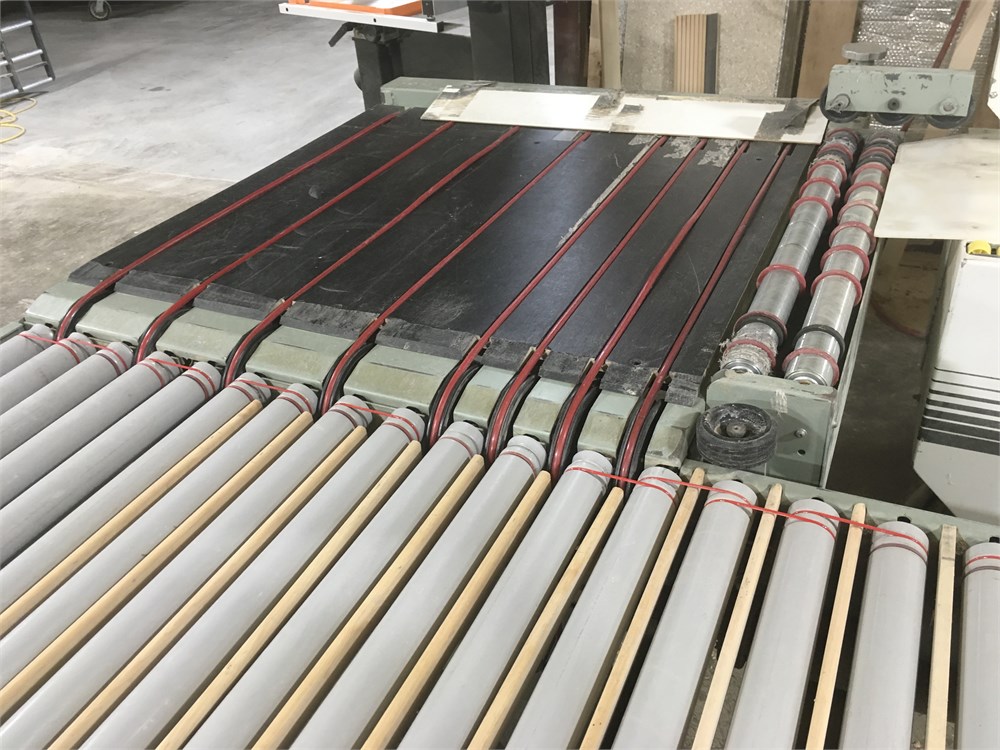

*This Lot is for the Doucet Feedback 36 Return Conveyor only, Jenkins Shape and Sand being auctioned in Lot #004-SC

Doucet Model #FB-36-3-11-G

Serial #2008-05-221

Specially designed to handle the fast pace of end-to-end feeding on Shaper Sanders and Edge Foilers. Available in two models, featuring 24 or 36 in wide receiving modules and return rollers. Standard receiving length is 36”, return conveyor length is proportionate to the length of the Shape & Sand or Edge Foiler it services.

- Feed rollers are driven by a D.C. variable speed motor, guide the part onto the receiving table.

- Set of top rollers prevent larger panels from tipping down while entering the receiving module.

- Polymer belts side shift the panels to the return rollers quickly and efficiently

- The return rollers, made of heavy duty PVC, are individually driven by welded urethane belts. These rollers are 2” lower than the pass height of the shaper, so parts can travel in opposite directions without interference.

- The transfer process occurs on a continuous basis, eliminating functional limitations typical of return devices with multiple cycle steps.

**Specifications as per manufacturer website and believed to be accurate, please however do your own due diligence as to exact specifications on this machine.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available