SCM "Olimpic K 560" Edgebander with pre mill & corner rounding  Ended

Ended

Items located in Jackson, MO

Jackson, MO

- Winning Bid : $13,000.00 USD Sold

- 70 Bid(s)

- High Bidder: M****n

SCM edgebanders, radial arm saws & more - Jackson, MO ( Closed #61059126 )

Columbia Casework in Jackson, MO is offering for auction machinery no longer required for production.

-

Item Location

Jackson, MO

-

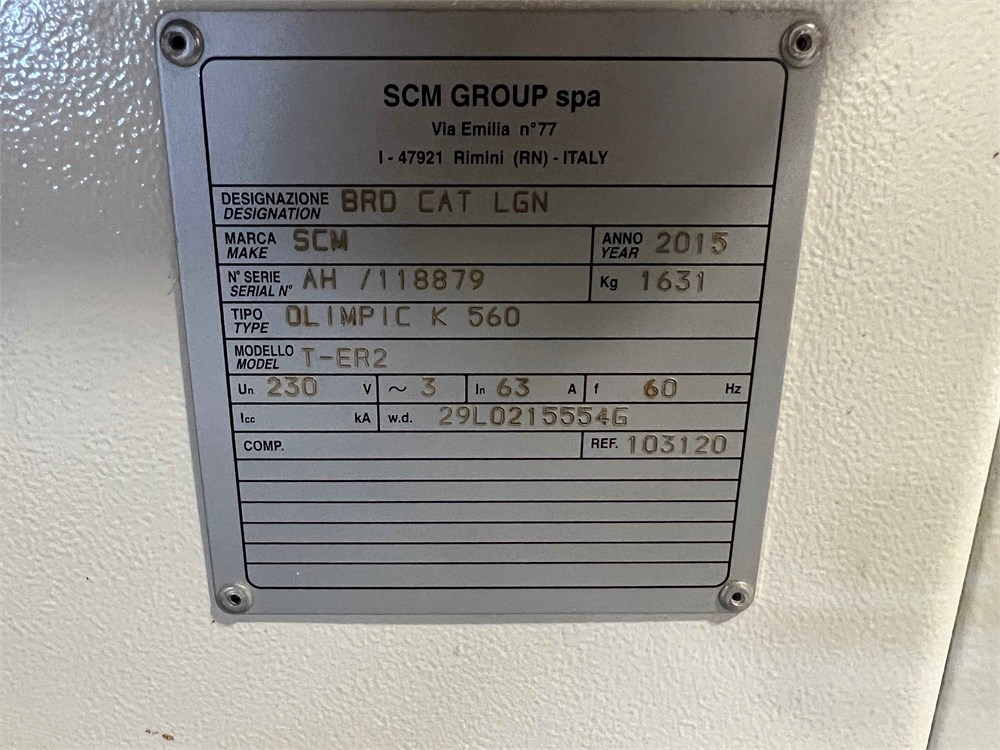

Make

SCM

-

Model

Olimpic K 560 T-ER2

-

Serial Number

118879

-

Year

2015

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Inspection Date

-

Final Removal Date

See main page for loading dates

-

Estimated Dimensions

14' x 4' x 6'

-

Estimated Weight

3600 pounds

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

200

-

Lot Notes

-

page views

129

Adjustable Infeed Fence

The infeed fence is manually adjustable with a mechanical digital readout for determining stock removal.

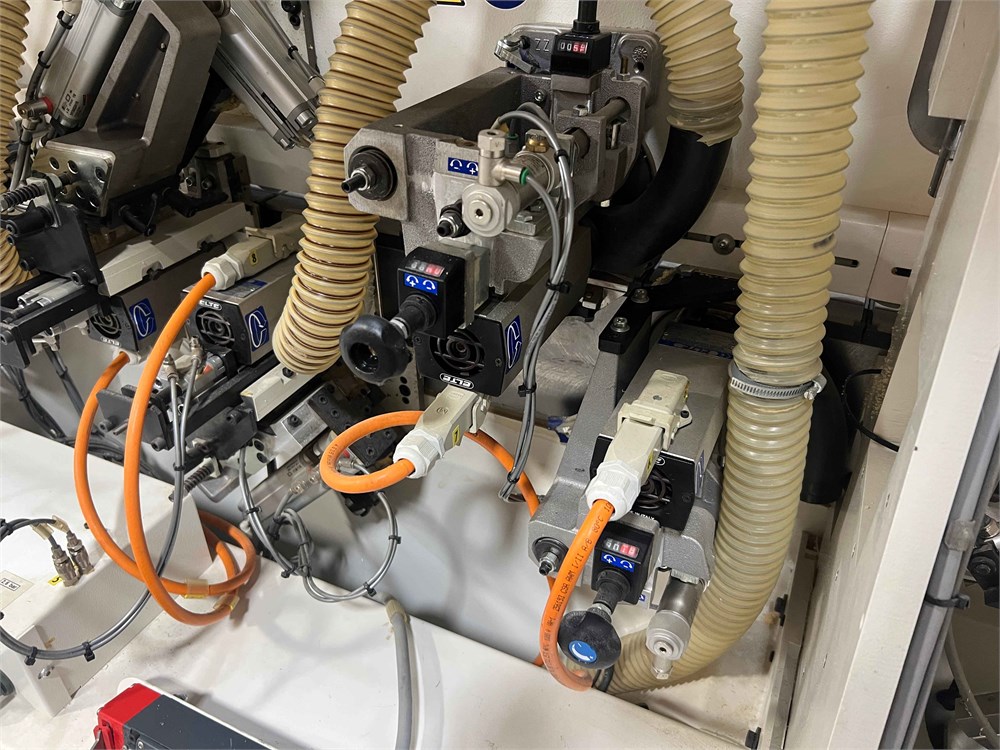

Pre-Milling Station:

To rectify/clean panels already sized and squared before the edge is applied. The unit is composed of two high frequency motors (2.0hp) with jumping action controlled through the PLC. The cutting heads are adjustable vertically. Diamond cutters are standard with 49mm height. Extra cutters included

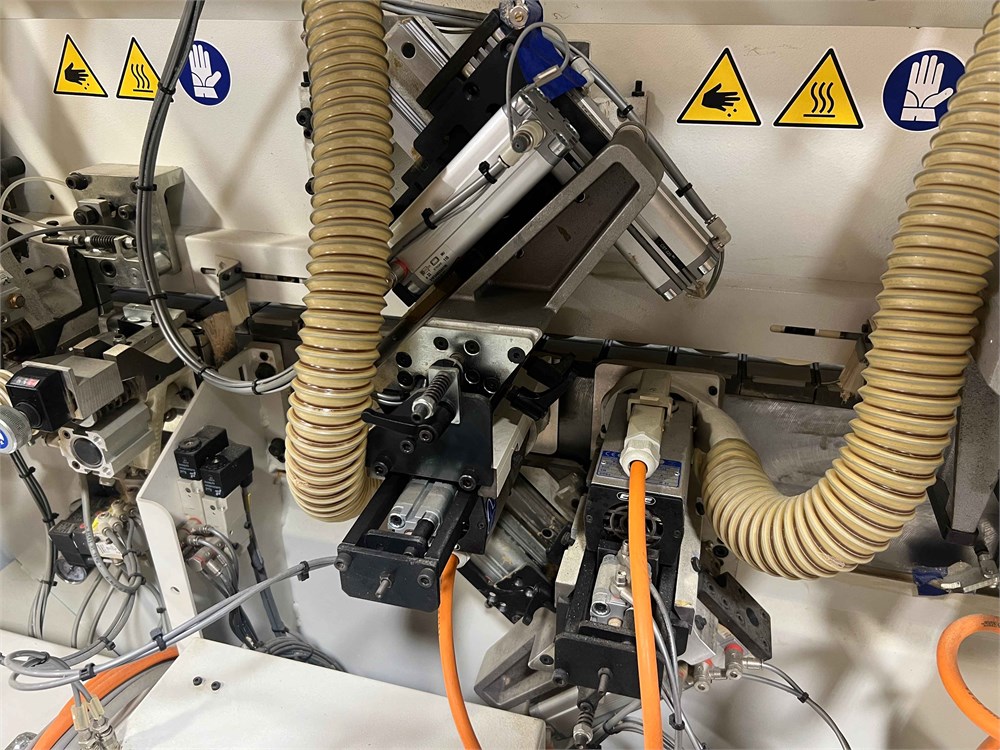

End Trimming Station

This unit is composed of two independent .50 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with automatic tilting of the unit from the control panel with two preset positions.

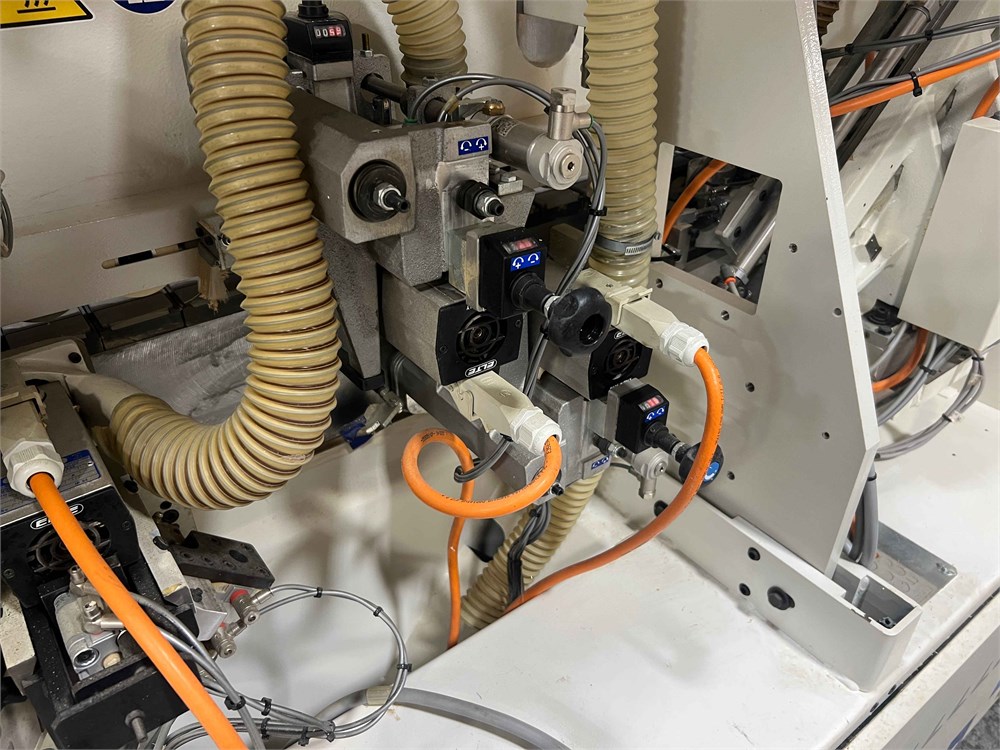

Multi Edge 2R Trimming Station

This unit is composed of two independent .7 hp motors operating at 12,000 rpm. It comes standard with servo positioning to process TWO different radii and infinite thin edges all through the controller. Independently controlled positioning, ie radius on top and straight edge on the bottom. Four different controlled axes adjustments. The unit has top/bottom/side copy wheels. The motors have quick release plugs to facilitate tooling changes. Unit comes equipped with the nesting package from the factory.

“ROUND-X” Multi Edge Corner Rounding Unit:

Two independent .50hp motors that slide on THK guides ensuring the highest quality finish. Servo positioning allows for the finishing of various thin edges and thick edge. Two controlled axes adjustments through the controller. Unit is designed to work as an additional set of trimmers for rounding the top/bottom as well as the front/rear corners of work piece with 3mm PVC edges. The unit is equipped with front and lateral copying devices and pneumatic blowers to clean the panel. Dust shrouds surround the cutter and travel with the unit as it trims. The unit can go from thin tape to 3mm PVC, through the controller, with no manual adjustments by the operator.

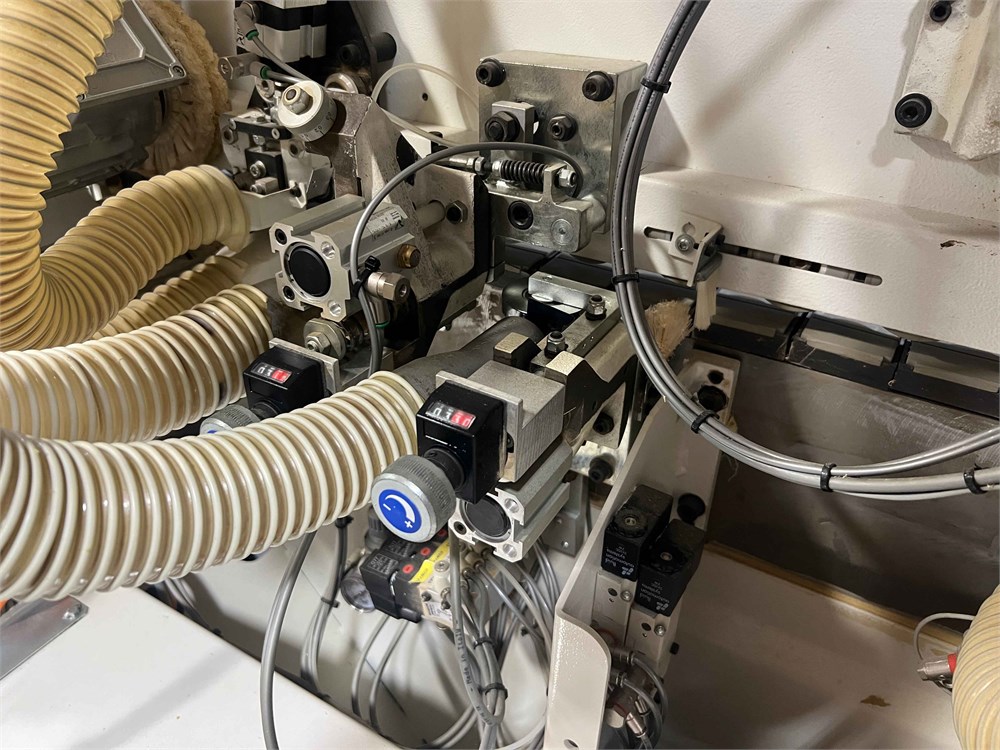

Profile Scraping Station

The profile scraping station designed to remove knife marks from thick PVC. The unit is equipped with servo positioning to process TWO different radii. Includes tool with two different radii, four controlled axes adjustments and the ability to independently control the top from the bottom. It has a large diameter horizontal copy wheel and side copy wheel device. Unit comes equipped with the nesting package from the factory.

Glue Scraping Unit

The unit eliminates any excess glue to help improve the quality of the glue joint. It comes standard with double copy wheels on the top and bottom of the panel, air blowers are standard to help keep the knives clean, the off fall is collected in the collection bin and it is pneumatically positioned through the controller.

Buffing Unit

The buffing unit has two .25 hp motors. It can also be tilted up to 12 degrees to provide a softer, more refined edge finish.

Acoustical Safety Enclosure

Custom dust collection (pictured) included

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available