Barberan "RR B8" Rotary Feed-thru Sprayer  Ended

Ended

M&M Recreation - Day 2 - Corsicana, TX

Corsicana, TX

- Winning Bid : $17,750.00 USD Sold

- 41 Bid(s)

- High Bidder: O****n

M & M Recreation Retirement Day 2 - Complete Woodworking & Finishing Facility ( Closed #62448204 )

Open House Feb 28th & Feb 29 8:30AM-4:00PM Contact Eric Beach 704-608-9830 or [email protected] - 3500 US-287, Corsicana, TX 75109

-

Item Location

Corsicana, TX

-

Make

Barberan

-

Model

"RR B8"

-

Serial Number

17520

-

Year

2010

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Inspection Date

See Homepage

-

Final Removal Date

See Homepage

-

Estimated Dimensions

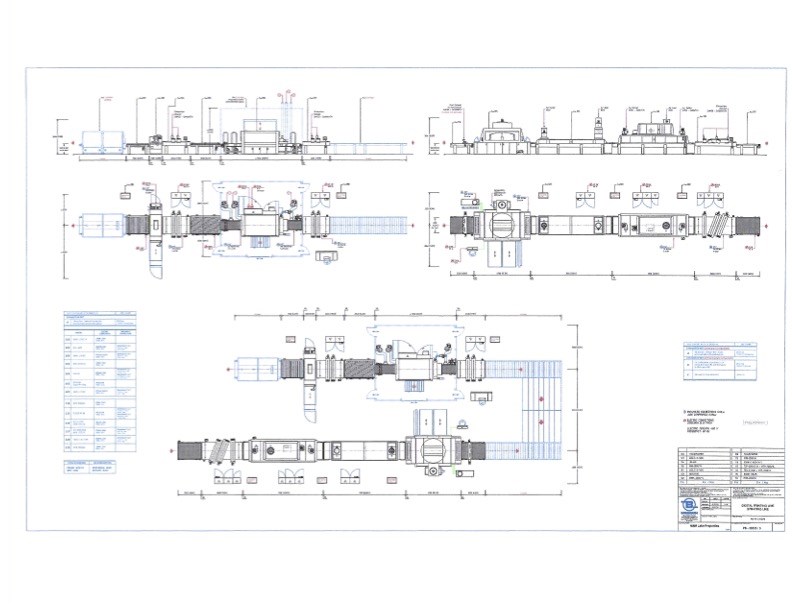

16'L x 102"W x 130"H (Sprayer - 60"L x 24"W x 48"H (Control Panel)

-

Estimated Weight

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

Rigger: Tom Preston - Preston Machinery 269-685-7591 [email protected]

-

Lot Notes

-

page views

1176

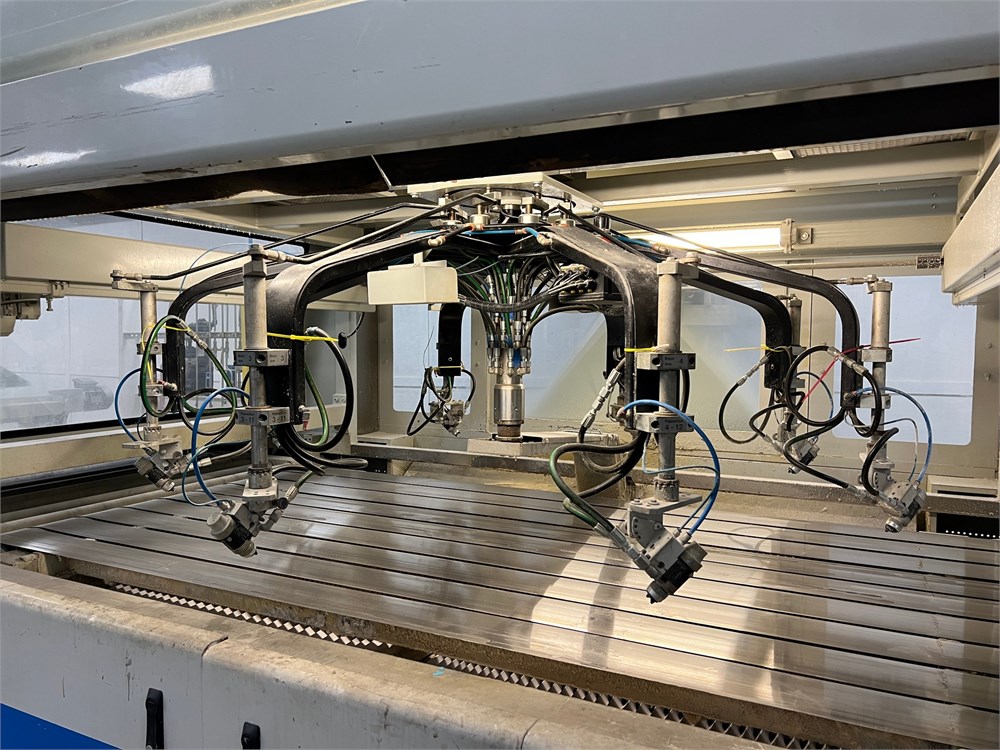

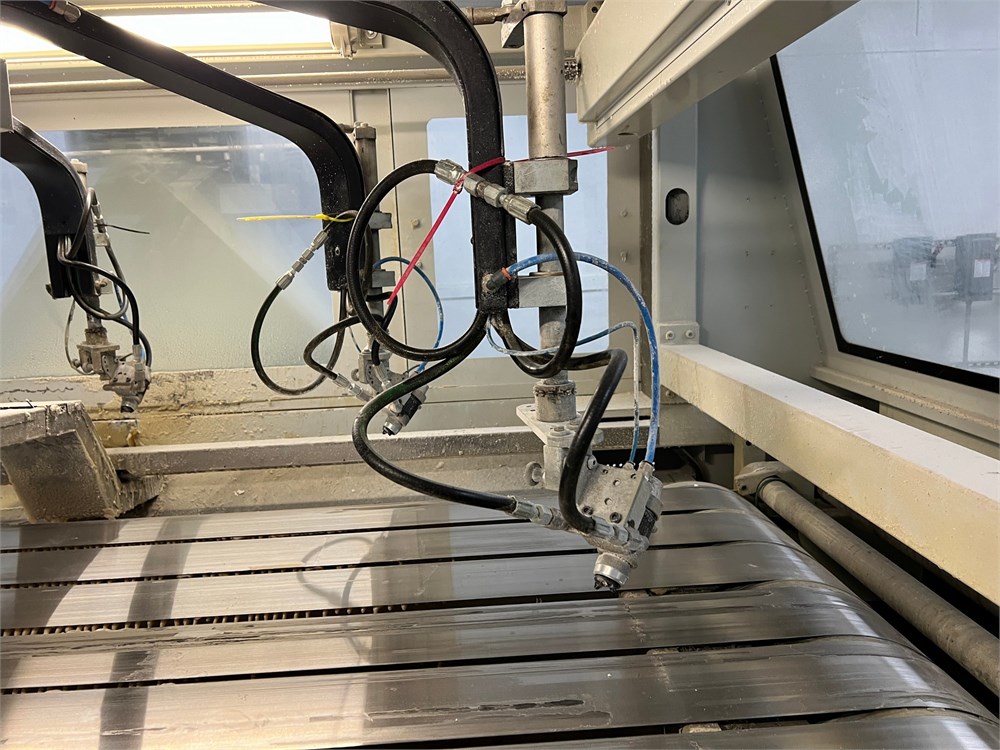

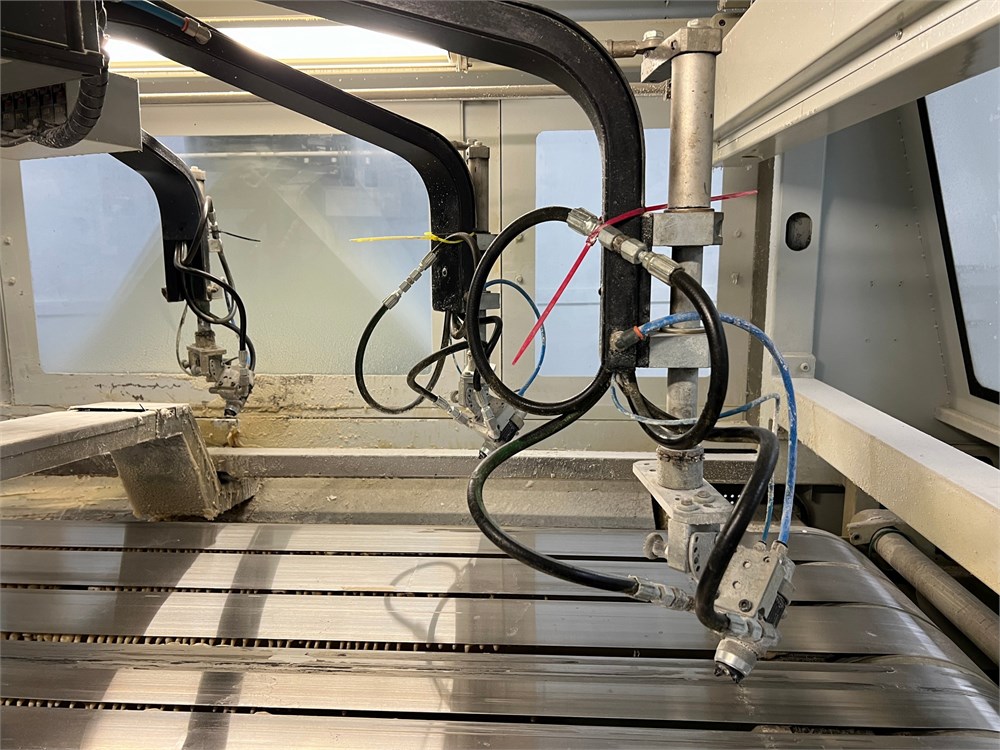

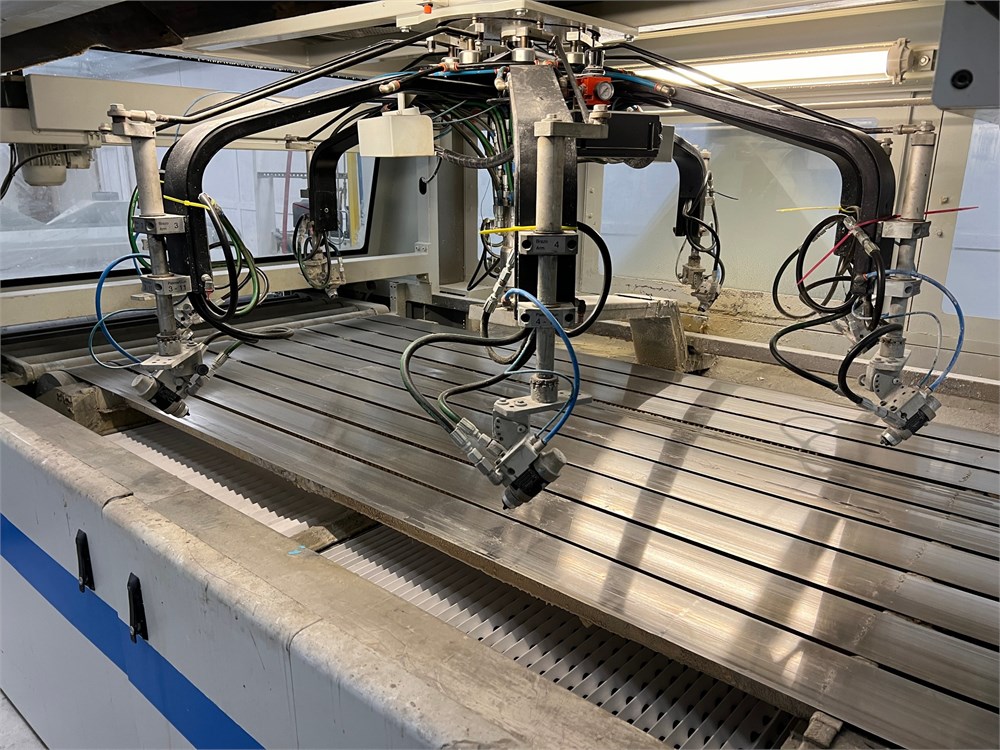

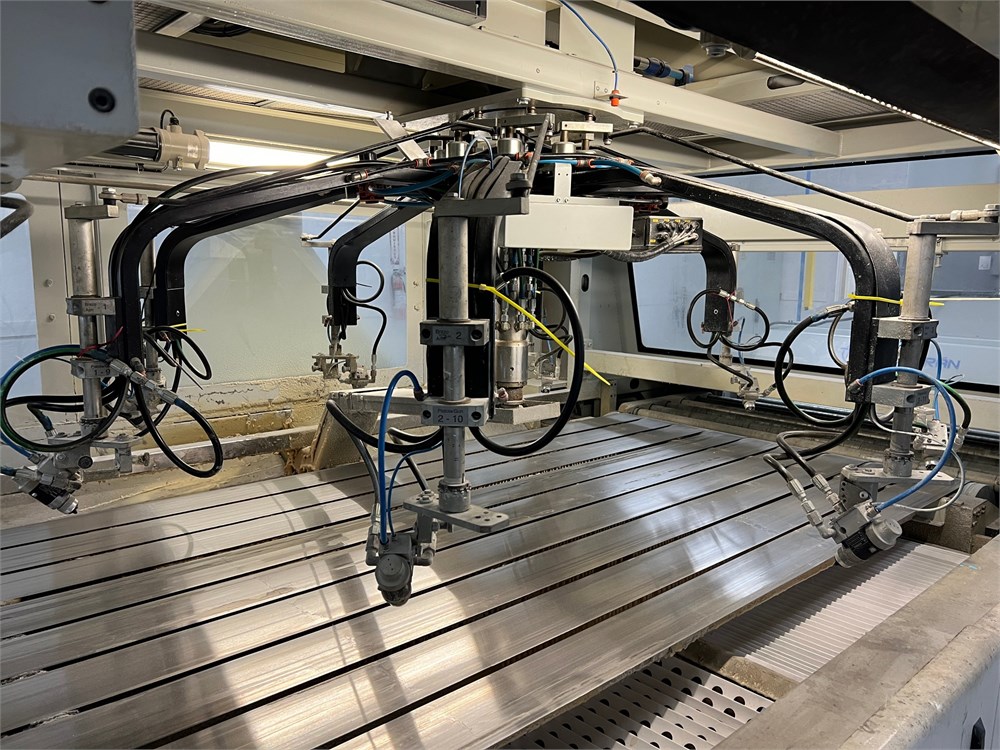

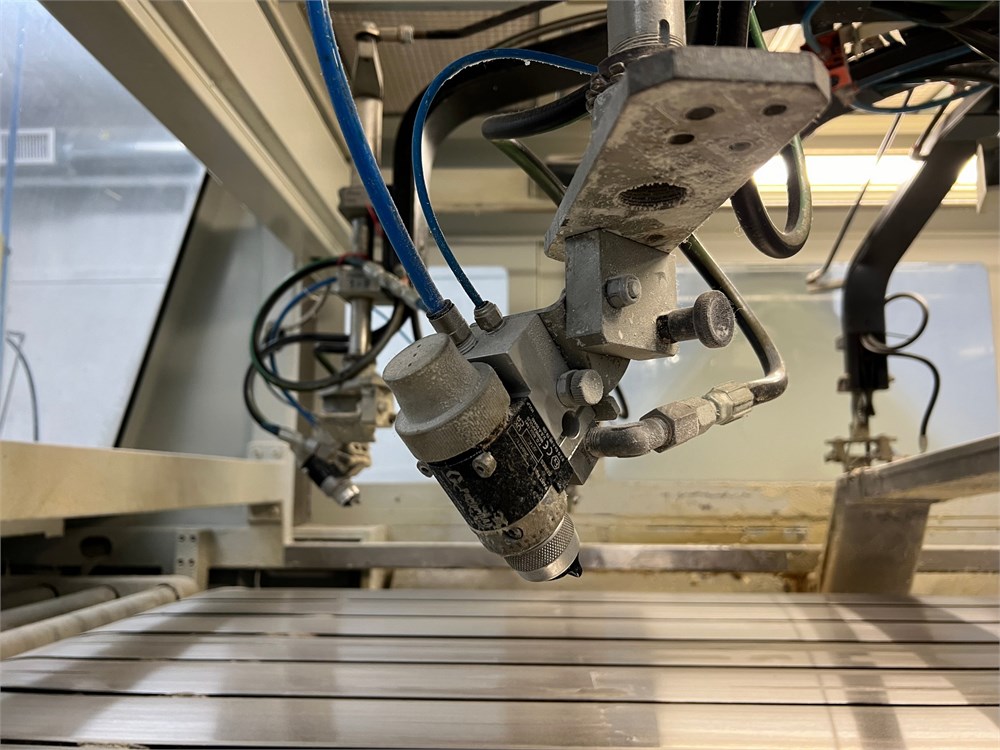

Barberan "RR B8" Rotary Feed-thru Sprayer

Rotary Sprayer with (8) arms; max. application width of 51" (1,300 mm)

Variable feed speed from 6 - 39 FPM (2 - 12 MPM)

Conveyor composed by 9 stainless steel belts 150 mm wide each, that allow a maximum weight of 50 kg/m2. Inverter controlled reed speed with electronic display look out.

Overspray recapture from the conveyor belts by means of a doctor blade with pneumatic approach by transport start. The captured material falls in a collecting tray in which a collecting scraper carries it to a tank placed close to the machine side to reuse it.

Cleaning of the belts two faces with Scotch-Brite sponges assembled on wet slippers with pneumatic counter-approach. The cleaning tank has a capacity for 60 liters of solvent.

Closed spraying cabin with over-spray depress exhaustion to the customer's network, through disposable filters beneath the conveyor, by means of a turbine. The in-coming alt carries the excess spray between the conveyor belts to the filters and follows its way out crossing another set of disposable filters before reaching the turbine. The front cabin-window rises motorized -safety lock protected- to facilitate the maintenance access.

Two Atex proof lamps illuminate inside the cabin.

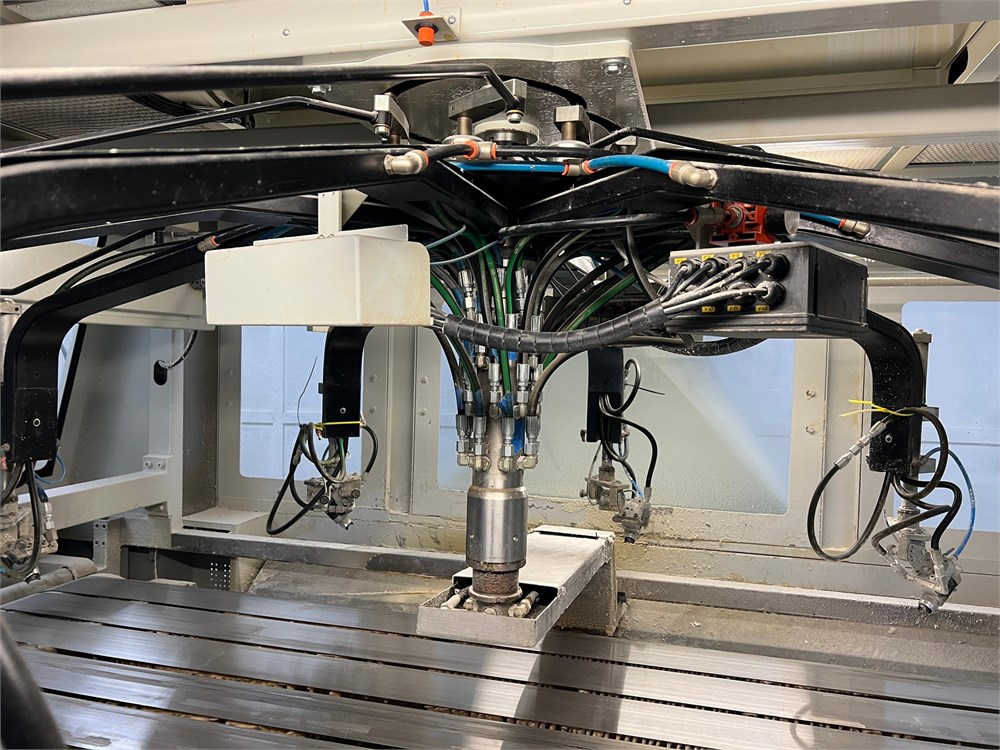

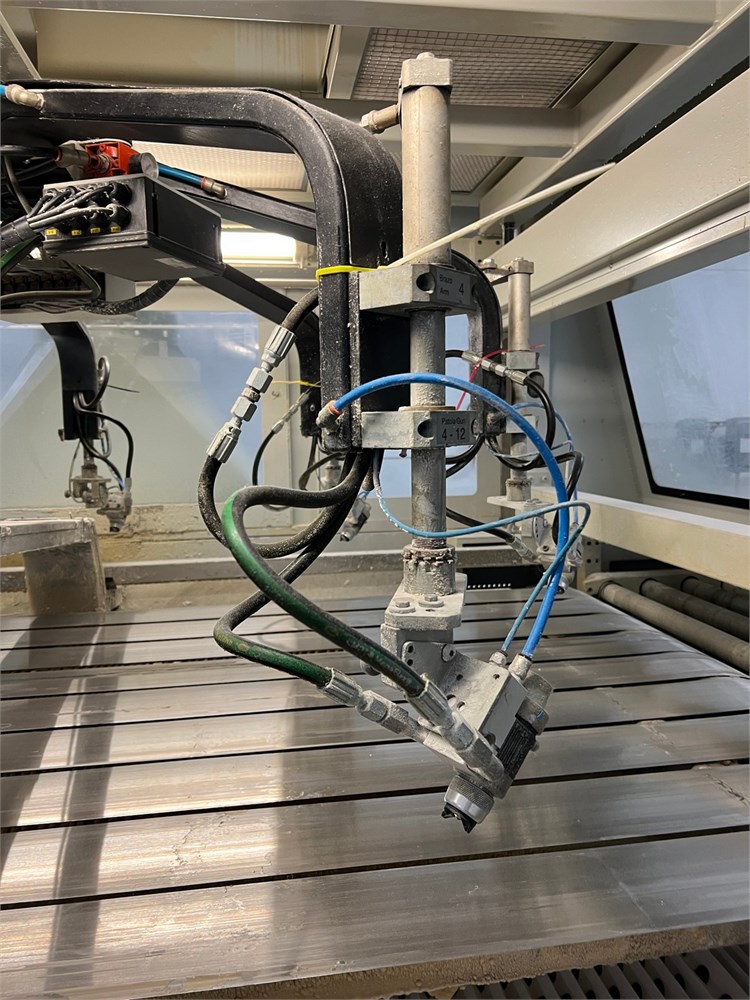

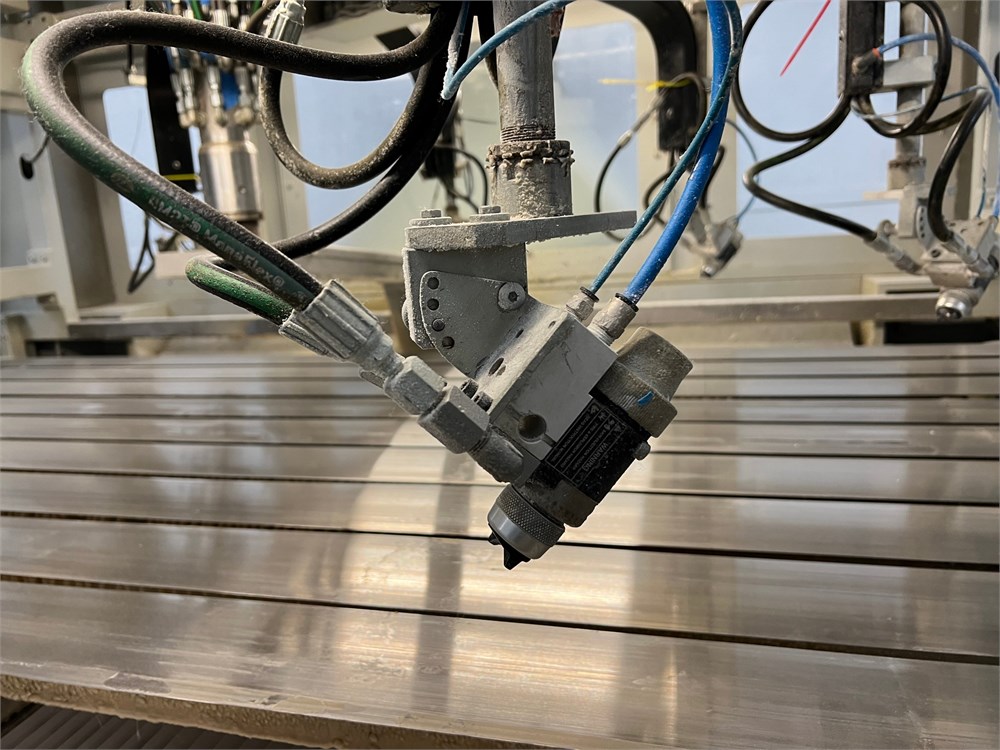

Spraying equipment composed by a rotary carousel with eight gun supporting arms. Eight supports can hold up 2 guns each one. The supports have a mechanical device that keeps constantly the same spraying angle. Rotary drive with inverter rotation speed control. Complete lacquer ducting for 2 independent circuits for 8 guns each one by means of a rotary coupling with 4 stainless steel chambers, able for water core lacquers. Gun holding arms with manual spraying angle regulation. Carousel motorized rising. Pneumatic installation with controls placed at the cabin's front.

Lacquer saving system through an electronic scanning that composed by: an infrared light station and a receiver barrier placed at the machine infeed, which scan every work piece shape with a 7 mm resolution barrier automatic gun self programming, managing the opening and closing of the guns, the turning and advance speeds, and - a multi function screen for speeds read out, sensors auto test, margins adjustment programming, etc., placed in a separate control desk linked to the spraying machine through a fast plug-in system.

Emergency stop by access window opening. ATEX proof Sprayer protection. Stand alone electric cabinet containing al the electric and electronic wiring (IP-55 protection).

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

Listed specifications were taken from the manufacturer’s published information and is assumed to be correct but not guaranteed.

Bidder is encouraged to inspect the machine, call with questions contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). MachineryMax does not ship- All buyers responsible for their own freight - For freight quotes please contact your preferred broker, or contact Aaron, at Always Trucking 541-608-6532

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.